Aviation

Euro Engine

As Airbus Defence and Space selected the new Catalyst engine for its Eurodrone Program, the European team of passioned, adept professionals celebrate the milestone.

Mar 2022

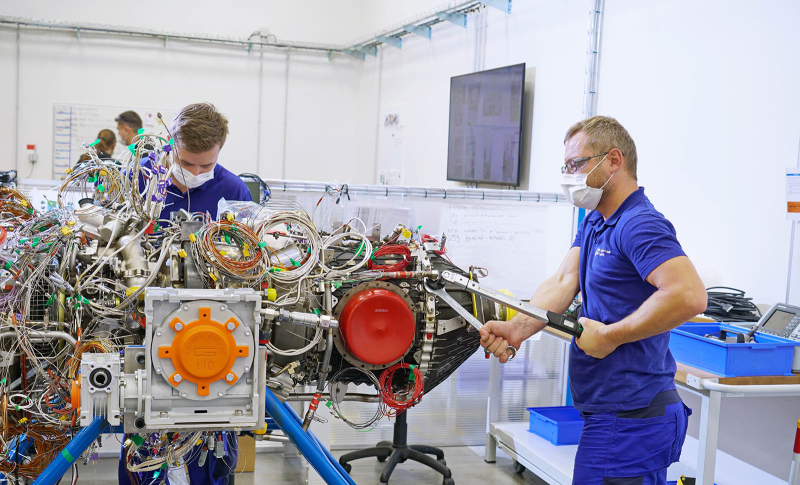

A team of some 400 European engineers spent the past decade developing a groundbreaking turboprop aircraft engine called the Catalyst. They combined technology from large commercial jet engines with digital engine controls in a way that opens new design options for plane-makers. Their engine also aims to deliver fuel savings and cut CO2 emissions by up to 20% compared with engines currently on the market, and it is already running on sustainable aviation fuel (SAF), sometimes referred to as biofuel, and even powers hybrid aircraft.

“In terms of technology, it is really an enabler for the aircraft manufacturer,” says Paolo Salvetti, sales director for military turboprop engines at Avio Aero. “A lot of the decisions that we made when we started developing the engine five years ago, they really positioned us well for the future.”

That future will include the Eurodrone, an unmanned aerial system that is being developed by Airbus and other European aerospace companies. The project, a collaboration between Germany, France, Spain and Italy, is expected to “strengthen European sovereignty by establishing and expanding an independent technological base in the field of unmanned aviation,” according to Airbus. “Eurodrone is designed to become one of the main pillars of any future combat air system, prepared for real integration into civil airspace based on minimal restrictions and easy transportability due to its modular design.”

The Catalyst engineering team, as well as the engine’s supply chain and assembly, is based in the European industrial ecosystem. The engine was designed and developed by engineers at Avio Aero in Italy, Poland and the Czech Republic, with the innovative design support of the Advanced Technology Center in Germany and the Engineering Design Center in Poland.

“We are honored to be chosen by Airbus to power Eurodrone,” said Riccardo Procacci, CEO and general manager of Avio Aero. “This is a huge milestone for the European aviation industry, enabling the growth of European Capabilities and sovereignty, and of course all our Catalyst team. We’ve invested in people, resources, and infrastructure to begin executing for the program immediately, and our teams across Europe are ready to get to work.”

Jean-Brice Dumont, head of military aircraft at Airbus Defense and Space, said the Catalyst was identified “as the best solution based on superior performance, lower developmental risk, better in-service economics as well as growth potential. In line with customer requirements, Catalyst will offer a truly European solution and will thus contribute to the overall role of Eurodrone as an enabler of strategic autonomy,” he said.

The engine’s first commercial application will be the Beechcraft Denali, a new, clean-sheet, high-performance turboprop designed by Textron Aviation. The single-engine plane will be able to cruise at 285 knots, carry 1,100 pounds of fuel and reach 1,600 nautical miles with four passengers and a pilot on board. “When you look at the development of the Beechcraft Denali as well as the Catalyst engine, it really went hand in hand,” says Alex Hunt, technical marketing adviser at Textron. “The Catalyst team was helping us with the engine requirements needed to maintain this airframe in order to really create a business-jet-style aircraft.”

"We are honored to be chosen by Airbus to power Eurodrone, this is a huge milestone for the European aviation industry, enabling the growth of European Capabilities and sovereignty, and of course all our Catalyst team"

Entering the market as the first turboprop engine ever made with 3D-printed parts, the Catalyst can deliver 1,300 shaft horsepower. It also comes with another new feature: The Full Authority Digital Engine Control, or FADEC, which controls both the engine and the propeller, is its brain. It consists of two fully redundant computers that listen to a slew of data from sensors about speed, air temperature and density, altitude and many more factors, and allows the pilot to fly the plane in an optimal way.

The Catalyst’s FADEC will allow the pilot to spend more time flying the aircraft than fine-tuning the engine’s settings. “The FADEC knows the conditions the plane is in, and it then optimizes the pitch of the propeller and the fuel flow around those conditions,” explains Jesus Lopez Ruiz, engineering leader for Catalyst military applications. “The pilot will no longer need to consult a chart to optimize the flight around the correct parameters with four separate levers. It will all be digitized. The pilot will just have a single lever. It will be like flying a jet.”

Eurodrone image in page is courtesy of Airbus Media Centre.