Culture

A century of reinventing turboprops

The first European aircraft engine designed and built in the Czech Republic took flight a hundred years ago, precisely in Prague where nowadays the future of turboprop engines comes to life.

Oct 2023

October is an important month in the history of the Czech Republic, as well as in that of Slovakia and the rest of Central and Eastern Europe. In fact, it was in October 1918 that the First Czechoslovak Republic was declared. The air force of the newly formed democratic state was born at the same time.

It was a somewhat troubled and complex period of modern history. World War I had just ended, while hostilities continued in Eastern Europe. This is why the newly installed Czechoslovak government prioritized Defense and related investments. One of the first goals was specifically the growth of military aviation, which, as a result, would also benefit civil aviation.

Czechoslovakia needed to bridge the industrial technology gap with other European countries, such as France, Germany and Italy - where at that time the ancestor of Avio Aero moved on from the A12 and A14 used in World War I, to intercontinental altitude or speed records and new monoplane and biplane fighters with the A20. Therefore, Czechoslovakia expedited its operations by calling upon national industries to work on the construction of new military aircraft.

Czech airframers quickly grew into design and serial production of reconnaissance light bomber and even fighter aircraft. Whereas the lack of locally made engines capable of sufficient power was solved through the purchase of foreign licenses. Apart from military applications, a gap was also felt for light sport and training aircraft, that required up to 100 shaft horsepower.

According to the reconstructions of Ivo Pujman, an historian expert in Czech aviation, then Czechoslovak Ministry of Defense set precise requirements: it had to be an aircraft capable of generating 50 shp of power at 1400 RPM, with a maximum weight of 1.6 kg per shaft horsepower, a level of consumption based on the maximum ratio of 0.25kg/1 shp per hour of operation. Furthermore, the engine had to be as uncomplicated as possible in terms of construction, highly reliable with minimal maintenance requirements, and had to pass at least one hundred hours of qualification tests.

An initial attempt was made by 1922 by the Breitfeld-Daněk company, which developed an engine in the 100 shp class. However, the project was not successful. Meanwhile, some thirty years earlier, an enterprising and experienced young mechanic, Josef Walter, had opened a bicycle repair shop. Within two decades, Walter & Co. had expanded production to motorcycles and had even become famous for its tricycles with in-house built engines, setting a reliability benchmark for that product.

"With the NZ-60 civil aviation could benefit from already perfected technology boasting significant and verified reliability"

Walter & Co. did even more, starting from origins evocative of the Wright brothers and following a path of industrial evolution typical of the greatest motorcycle and aircraft brands: it specialized in the design and construction of aircraft engines. In around 1920, it was already producing engines under license for the German BMW company and was therefore contracted by the Czechoslovak defense to build the new engine for the air force.

The company, which in 2008 would become GE Aviation Czech and more recently part of Avio Aero - a GE Aerospace company, did not miss the opportunity. In 1922, the company completed the design of a new air-cooled piston radial engine, led by Chief Engineer Jan Novák and supported by the talents of engineers such as Zeithammer, hence the name of the first “made-in-Prague” engine, NZ-60. Also, supporting the design was Prof. Šimek and the Prague Technical University, the oldest in Central Europe, with which, to this day, the engineering team in Prague collaborates in an active and virtuous way.

The Ministry of Defense immediately appreciated the brand-new engine inspired - in the shape of the cylinders and their heads - by the famous Walter motorcycle engines and ordered two prototypes, requesting that serial production begin by June 1923.

"The cylinder body was made of steel, while the cooling system was machined from cast aluminum," said Lukas Popelka, Testing Engineer at Avio Aero Prague, and a great enthusiast as well as connoisseur of aviation history. "In the case of the NZ-60, the air force purchased the initial series production, with which slight or even major modifications were introduced, such as dual ignition. In this way, civil aviation could benefit from already perfected technology boasting significant and verified reliability.”

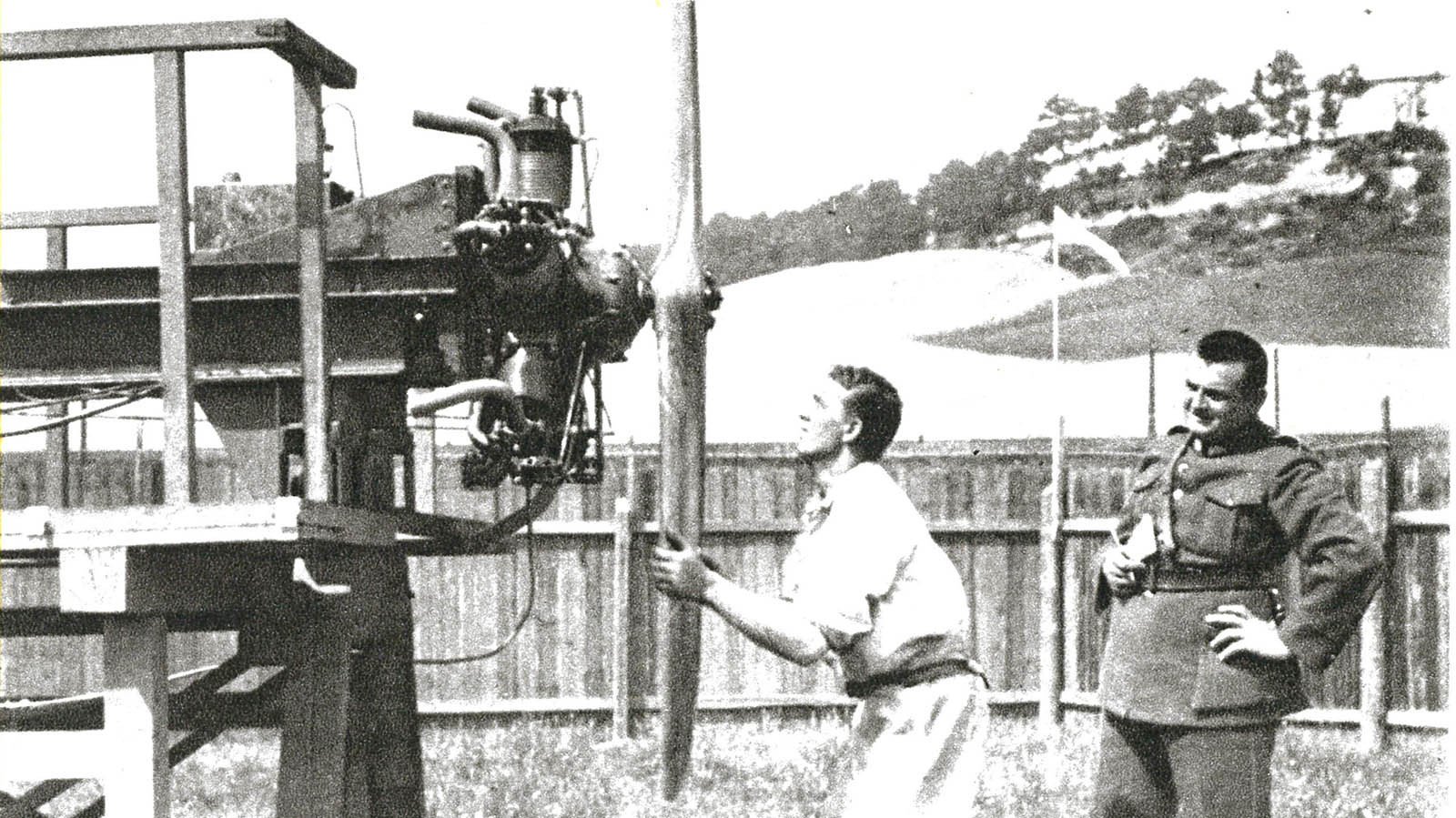

Walter & Co.’s first engine underwent its very first ground test in June 1923, already equipped with its twin-bladed propeller. “The test bench was even capable of attitude testing to simulate climb and descent, and the engine passed endurance tests of more than 100 hours with excellent results in terms of stability and fuel consumption”, Popelka added.

As they say, the rest is history. The ministry of defense welcomed the test results, and the engine made its maiden flight on October 23, 1923, installed and integrated on the BH-5 aircraft in cooperation with Avia (also a famous Czechoslovak aircraft factory) for which it had been chosen. The BH-5 underwent a test campaign lasting more than a month, with Air Force pilots extremely satisfied.

In the wake of the NZ-60’s success with the BH-5, new models of advanced aircraft were born, such as the BH-9 for training and the BH-11, also ordered by the Ministry of Defense and, as before, equipped with the same high-performance engine. In total, 188 NZ-60s were built until 1930. It was a remarkable number for that time, and several records were even broken in the light aircraft engine and air sport categories.

The centenary of the first engine in Prague comes at a significant time, as the most advanced turboprop engine ever designed and produced in Europe, the Catalyst, is progressing on its intense test campaign for certification, accumulating nearly two thousand hours in flight and redefining the technological level of its market segment.

"We cherish an exceptionally valuable heritage, rich in parallels and historical intrigue that have inspired next engine models such as the M601 or legendary people such as Novak. The one and only, he was the one with immense responsibility who is a model of leadership for all of us. We have adopted his principles on the subject of R&D and have implemented them right up to the development of the H80 engine, for example," Popelka concluded.