Invent

Pride of Prague

An inside look at GE Aviation Turboprop headquarters, guided by the local leaders through its heritage, tech capabilities, bright outlook and European integration with Avio Aero.

Nov 2020

Curious coincidences, alliances and industrial synergies, among others, can often be found in European history that bridge the twentieth century and the new millennium, marking parables of technological innovation and progress.

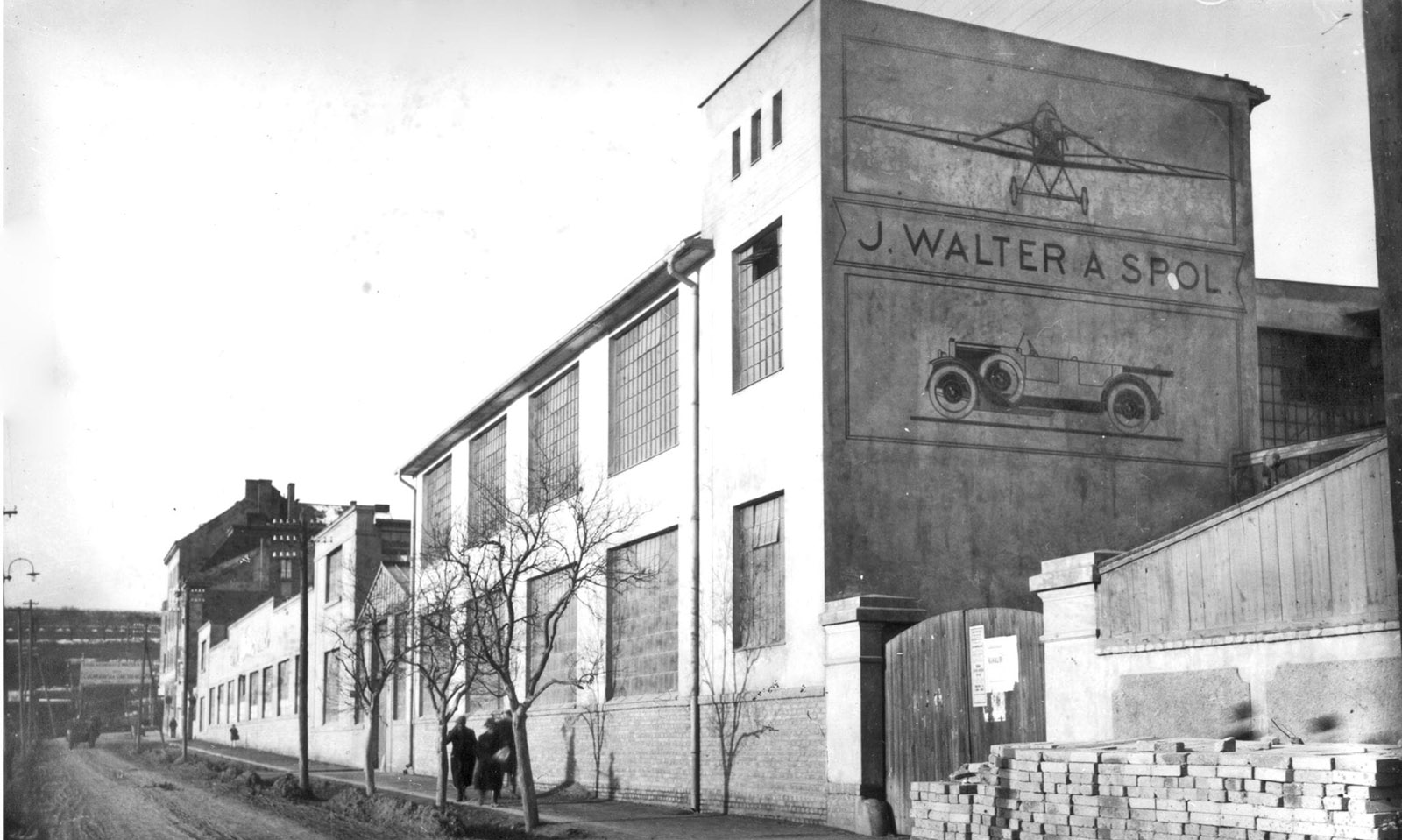

Walter Engines was founded in 1911 in Prague, in the Czech Republic. It manufactured motorcycles and, starting from the 20s, it specialized in aircraft engines, consolidating the capabilities of the national and European aeronautical industry (worldwide, there are very few countries capable of building both aircraft and their engines). Until 1954, the Czech company was also a licensed automobiles manufacturer of the Italian brand that was a leading player in the sector at the time, Fiat.

A century later, in 2008, Walter Engines was acquired by General Electric, becoming GE Aviation Turboprop - the international headquarters for turboprop engines - which today finds itself integrated within Avio Aero (founded in 1908 and part of GE since 2013). Once again, it found itself working with an Italian company to write a new chapter of technological innovation, this time in the aeronautical industry.

"The acquisition of Walter was the first time in more than 50 years that GE Aviation entered the industry of turboprop engines in its own right, catering for a customer base with completely different product requirements and needs. It turned out to be a wonderful learning experience for both: the historic Central European company acquired operating rhythms, the consolidation of production processes and new advanced technologies from the world’s largest industrial conglomerate. It also proved to be a great opportunity in cultural terms since there is now an international team in Prague with many diverse skills and from many different backgrounds."

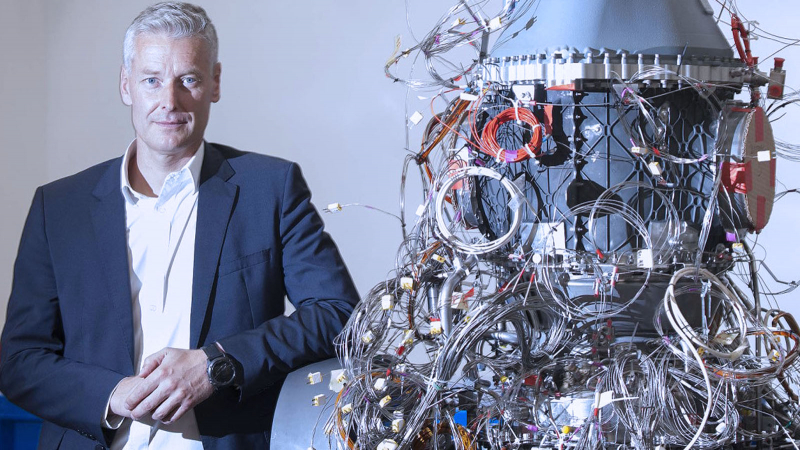

The historical excursus of Milan Slapak, General Manager of GE Aviation Turboprop, also reveals the philosophy adopted towards customers in the turboprop market: “high-level service, based on solid engineering expertise, based in Prague and supported by a strong, global, specialized network".

Slapak has been at GE for 21 years. He previously worked in various GE business (Transportation, Healthcare, Corporate and finally Aviation since 2009) and joined as a young engineer through the Supply Chain Talent Program, later embarking on a managerial career in commercial areas that took him to a number of countries (USA, France, China, Italy). At the same time, he was also President of General Electric for the Czech Republic and Slovakia, as well as Vice President and member of the American Chamber of Commerce and the Confederation of the Czech Aeronautics Industry.

The M601 is the famous turboprop engine created in 1968 by Walter: currently it has accumulated over 21 million hours in flight and it was from this powerplant that GE Aviation, only three years after the acquisition of Walter, created the new and enhanced H Series. “H-series engine is pretty much the same size and weight as Walter’s M601, however it produces 100 more shaft horsepower from the same amount of metal” says Slapak.

"H80 engine received its EASA type certificate in December 2011, the first GE turboprop engine was certified right in the year when Walter would have celebrated its 100 years anniversary... it was a cool gift"

The H Series engines, developed in 2011 in three versions covering a range from 750 to 850shp, were the first major successes of the new-born GE Aviation Czech. They offered more power than the M601, adding GE technology and equipped with an EEPC (electronic engine and propeller control) that revolutionize the handling of small propeller-driven aircraft.

"The H Series has accumulated more than 560,000 hours of service and is present on every continent, with Europe, Africa, Russia and Latin America on top," Slapak added. "Today we serve a fleet of about 1250 engines (in the M601 and H Series) throughout the world which are used by the most renowned private and regional aircraft manufacturers: not only the compatriot Let with the famous L410 - adopted by various regional airline companies, including for medical or agricultural rescue purposes - but also Thrush Aircraft and Beechcraft”.

It is a series of powerful, reliable and innovative engines, both cost-effective and low maintenance, capable of operating in remote areas of the world and hostile climatic-environmental conditions. "There is also the acrobatic version of the H75, soon to fly with the new Diamond Dart 550 introducing some new technological features for this niche market... it's a very exciting product," Slapak said. “While the development of the GE’s Catalyst engine started from a clean sheet and the product itself represents a brand-new line in our portfolio.”

From the facilities close to the center of Prague, these turboprop engines come out fully tried and tested and ready to be installed on aircraft. In the case of compatriot Let, the fact that the aircraft manufacturer is only a few kilometers away from the aircraft manufacturer also allows optimal coordination between engine and aircraft, as well as opportunities for joint R&D.

GE Aviation Czech's headquarters covers a total of about 22,000 square meters, accommodates more than 400 people, half of whom are engaged in production and testing activities on 13,000 square meters. It was here, in addition to the M601 and the H Series, that the first Catalyst engines were assembled. These engines have been the flagship of the collaboration between GE's European teams since its conception, and will go into mass production upon the Cessna Denali's entry into service.

This is the one and only GE Aviation facility in Europe where an engine is both manufactured and tested, starting with the single components upstream of the process. "This is also due to the unique characteristics of the turboprops and their size," explained Mario Balestrieri, Plant Leader of GE Aviation Turboprop. "The Prague headquarters look at the supply chain in its entirety: we start with the input of single parts or modules and arrive at a finished product, which is then tried and tested on site straight after assembly. This is unique for our site and involves a highly developed certification system and industrial operations, most notably the overall testing of the engine”

Here - again in line with the historical synergy - many Italians are members of the team, and it is typical in the field of engineering to find many different nationalities. Balestrieri, specifically, holds a brilliant career in the Global Supply Chain. He started at the Avio Aero Pomigliano d’Arco site and moved on to roles of increasing responsibility at production centers in Italy, as well as in the Netherlands and China, and nowadays at the factory in Prague.

"Such opportunities for comparison and learning on an international scale allow you to broaden your mental horizons and develop new skills and meet people from all walks of life... this is perhaps the most valuable sense of globalization"

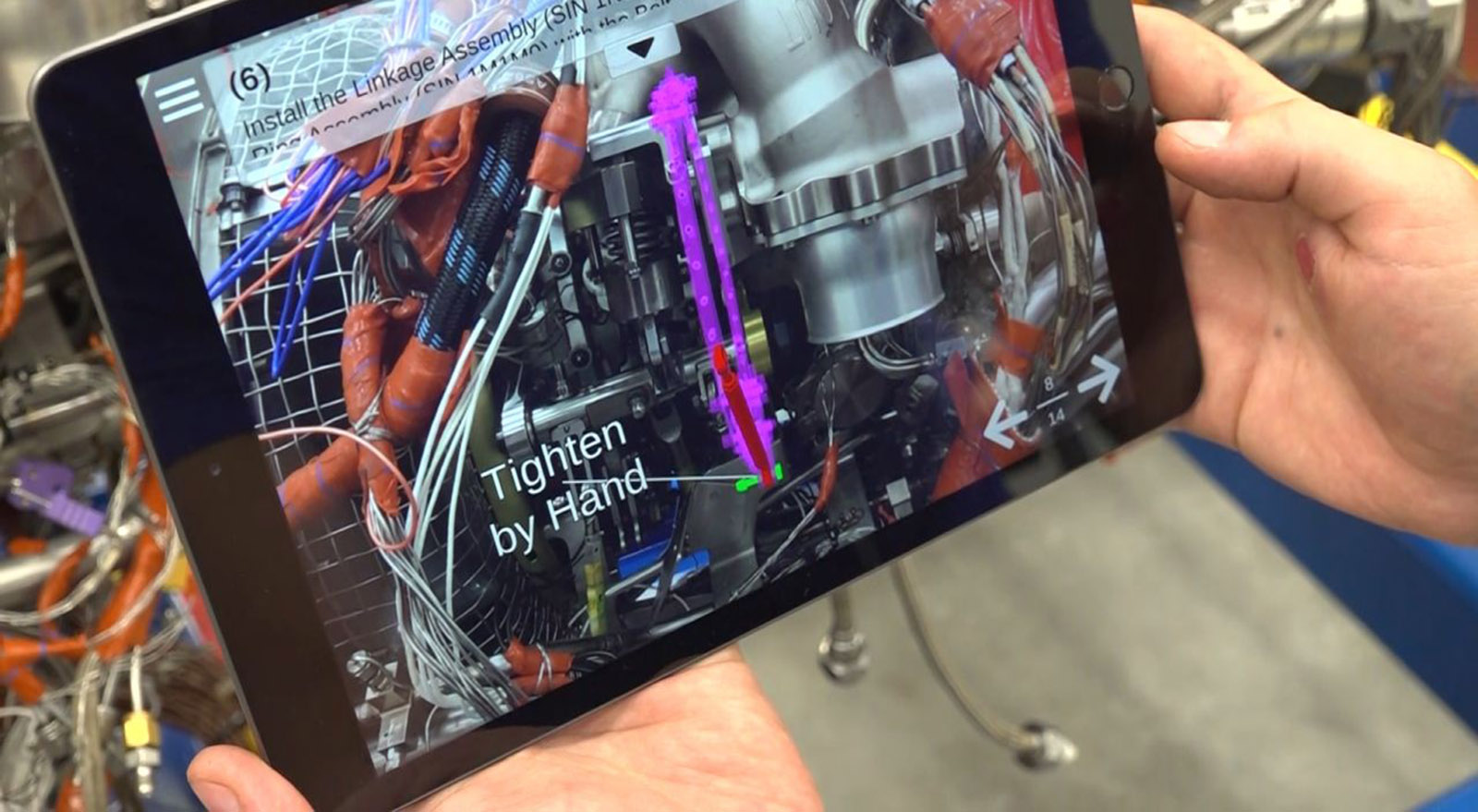

"We are implementing several Lean workouts to improve the approach and method both in the workshop and in the office, and are experimenting with tests that involve the use of digital technology (AI and Virtual Reality)" said Balestrieri, in relation to how he has exploited his wealth of experience. "I have had the opportunity to acquire many diverse skills, not only professional and technical but also cultural and human. I am now capable of looking at a business in its entirety, and deal with product lines that are well established but also offer great prospects for innovation and development."

GE's turboprop engine headquarters in Prague is therefore a very fertile ground for innovation and the development of new technologies - particularly digital and sustainable ones - or for collaborations and networking with centers and universities that, together with young talent, have potential for impact in the aeronautical industry.

"Research and innovation are the only paths to future, especially in the case of turboprops" Slapak added. "The long-term partnership with CVUT has a value of about 80 million dollars and includes not only sharing for new inventions, but also the assets of four latest generation test rooms and a flight test center. There is no other university in the world with such facilities. To this, we must add the work with the aeronautical research institute VZLU which is testing the new acrobatic version of the H80 (optimal power-to-weight ratio and the only engine with digital controls in its category). And the virtual reality project for the workshop is also being carried out in collaboration with ESA (European Space Agency)."

With this in mind, GE Aviation Czech is able to immediately explore hybrid-electric potential in programs such as the Catalyst and H Series, as well as to focus on projects that extend the life of engine components or that aim to reduce fuel consumption - and therefore emissions - in line with European ecological objectives.

Set in the new millennium and in the field of innovation, integration with Avio Aero is of further value. Slapak said: "being able to count also on the European research network coordinated by Avio Aero is a great benefit, together with the opportunities for cooperation in the field of military applications."

Cover and page photos credits, GE Aviation 2019 ©