Future

The key to electrification of flight

Aeronautics research of today could bring within the next decade hybrid-electric solutions based on turboprop engines architecture, the most promising for lowering emissions.

Jul 2022

In early June, the European Parliament announced a momentous change: from 2035, it will no longer be possible to buy cars powered by diesel fuel or petrol. This breakthrough also forms part of the Green Deal, the European plan focused on climate, energy, transport and taxation for a more sustainable society in the future and to reduce net greenhouse gas emissions by at least 55 percent by 2030 compared to 1990 levels.

The automotive sector - which has already been bringing hybrid-electric cars to the market for over a couple of decades, and that more recently has introduced the so-called plug-in or full-electric - will therefore be uniquely devoted to such technologies. A similar regulatory shift would also be desirable for air transport which, after the pandemic halt, is resuming its upward trend in terms of passengers, albeit with difficulty (forecasts project 4 billion travelers by 2024).

Although the SAF (Sustainable Aviation Fuels) are a prompt and effective answer to reducing in-flight emissions, and even if the first scheduled flights employing SAF have taken place successfully and satisfactorily, the time has come to focus on technologies that will be able to drastically and, eventually, totally reduce CO2 emissions: more ambitious, zero-emission technologies such as hydrogen, and those closer to being achieved, such as the electrification of flight.

“Our studies for the development of new engine architectures have actually already begun with the MAESTRO and IRON projects as part of the main European research program, Clean Sky2, which this year launched its continuation phase called Clean Aviation”, explains Silvia Calabrini, Enhanced Turboprop and Hybrid-Electric Program Manager at Avio Aero, speaking from a showcase of Clean Sky 2 key innovations and results organised under the patronage of MEP Marian-Jean Marinescu and on exhibit right at heart of the European Parliament.

“MAESTRO focused in fact on small aircraft with turboprop engines (and our Catalyst benefited of high-efficiency technologies born within this project) and has matured and validated propulsion technologies that have resulted in fuel consumption reductions of up to 20 percent, as well as in reductions in CO2 and NOX emissions. By contrast, the IRON project, in collaboration with Leonardo, immediately focused on regional transport aircraft with solutions involving next-generation turboprop engines or innovative architectures such as the Open Fan engine.”

Together with Avio Aero's R&D team, Silvia Calabrini has traveled along trajectory - especially when it comes to these two projects that evolved to be renamed e-MAESTRO and e-IRON - that has focused on hybrid-electric configurations capable of lowering gaseous emissions along with noise and fuel consumption. “Studies for electrification in aviation also find development in the IMOTHEP program, which is part of Horizon 2020, in which we are developing innovative solutions together with other industrial and research partners,” Calabrini adds.

“We have been supported in this development journey by our European engineering colleagues with whom we have been working assiduously for quite some time: AAT in Munich, EDC in Warsaw, Dowty Propellers in the UK, GEAC in the Czech Republic and even TTC in Istanbul. Moreover, let us forget that our parent company, GE Aviation, has signed a partnership with NASA and Boeing for a MW power-class hybrid-electric demonstrator.”

We are talking about hybrid-electric rather than full-electric technology - which is something that has been flying small aircraft or eVTOL (electric vertical take off and landing) aircraft for quite some time now for future urban air mobility - because we are thinking of solutions for aircraft carrying well over a maximum of 8-10 people. And the key fully lies in that capacity of 1MW power. “This amount of power is what is needed to transport about twenty people,” says Sergio Salvano, Engineering Leader at GE Aviation Turboprop, part of Avio Aero.

"We have studied solutions for future aircraft based on a combination of electrical components with the traditional thermal machine, a hybrid system harnesses multiple sources of energy that work in synergy with each other"

“By combining this power with the electric source, it is possible to reach more than 2MW per wing. And, with 4MW of power developed altogether on board a regional aircraft, it is possible to transport up to 80 passengers: this is why turboprops are considered the forerunner of hybrid-electric solutions in air transport, such as to allow for the consolidation and maturation of brand new technologies,” Salvano explains.

Turboprop engines are therefore more efficient by nature than large turbofans because of their weight and size, as well as because their very structure, which includes a propeller and blades, allows more direct and thus efficient flow utilization. But there is more.

“The solutions we have studied for the propulsion of such a future aircraft,” Calabrini continues, “are based on a combination of electrical components with the traditional thermal machine. A hybrid system harnesses multiple sources of energy that work in synergy with each other: in the case of an aircraft's hybrid-electric engine, a heat engine and electrical components - such as generators, electric motors and power converters - coexist, with or without storage systems that aim to generate the necessary thrust.”

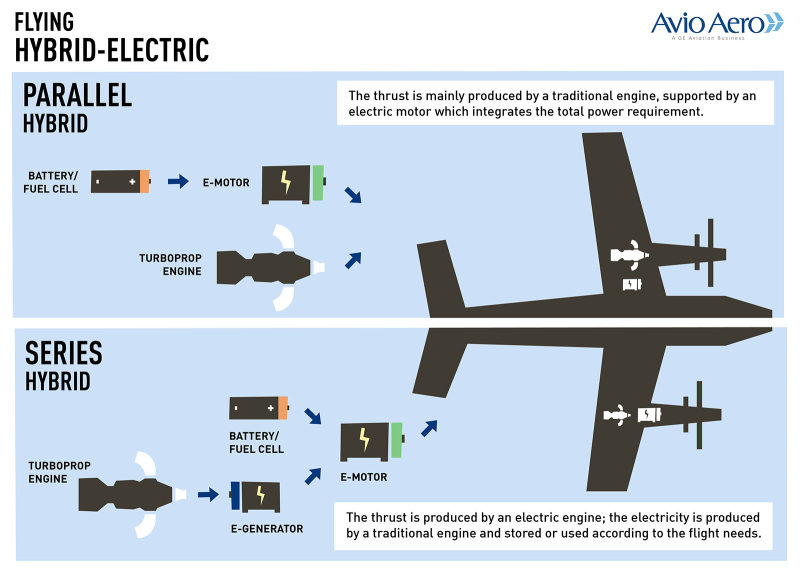

Basically, the combination modes can be summarized in three configurations: turboelectric, parallel-hybrid and series hybrid. In the first, the heat engine (a turboprop, or rather turboshaft in this case) powers a generator which in turn supplies power to multiple electric motors (so-called diffuse propulsion because it uses the entire wing surface and distributes multiple propellers over the aircraft). In the other two, batteries or fuel cells (a system that uses hydrogen to generate electrical energy from an electrochemical process) and a possibly more active role for the turboprop engine come into play.

“In the parallel hybrid, thrust is produced primarily by a conventional heat engine, supported by an electric motor that supplements for the total power requirement,” explains Calabrini. “By contrast, in the series hybrid, electrical energy is produced by a generator connected to the heat engine and, depending on the phase of flight, electrical energy is either stored or used to give more power to the motors and propellers. The choice of configuration is what we are studying today, with the goal of providing the required power and maximum safety conditions while reducing emissions and maximizing propulsive efficiency. Parallel hybrid also stands out because it allows for the decoupling of the two sources (electrical and thermal) with a positive impact on safety.”

Of course, the configuration of the aircraft changes along with the engine and its architecture: not only will it have to accommodate new and different components in terms of weight, size, and geometry, but conventional components may also undergo changes. New aircraft architectures, in fact, require ad hoc compliance and design studies to handle high levels of electrical power and heat, optimize component placement, and ensure safety levels and, finally, certification.

This is one of the reasons why it is essential to work hand in hand with aircraft manufacturers who, like the engine builders, are on a mission to bring their products to maturity, to see them fly by 2030 and enter service by 2035. Along with this, as in a logical collective effort, airports and service or supply infrastructures will also need to transform in a sustainable and safe way (especially when dealing with an element such as hydrogen, for example).

“Goals and timelines are challenging, but Avio Aero is ready to be an active part of this transformation. And Clean Aviation is an opportunity to accelerate the transition towards innovative architectures, believing in the Turboprop’s potential within the program’s ‘Hybrid-Electric’ technology pillar. One day, we could see the first environmentally friendly hybrid-electric engine soaring Europe’s skies”, Calabrini concludes.

Images from Brussels exhibition are courtesy of Clean Aviation.