Future

Flying “bio”

Fuels made with renewable sources are already a reality and maybe the biggest part of the solution to achieve sustainable targets that the entire aviation sector has set itself for 2050.

Jan 2021

Generating renewable energy for human needs is among the most concrete and effective way to a cleaner planet, as well as a counter measure to the increasingly visible effects of climate change. Aviation wise, flying aircraft powered by more sustainable fuels than petroleum has been possible since 2009, when the first type of Sustainable Aviation Fuel (SAF) was approved by the standards organization ASTM International.

Jet fuel that is not (or only partially) petroleum-based can therefore be defined as SAF if it meets various sustainability criteria. Current aviation regulations allow the use of kerosene jet fuel for in-flight use and for distribution to airports, as the two most common being Jet A and Jet A-1: SAF, when blended with Jet A/A-1 meets the product standards, with a significant difference in the raw materials (or feedstock) from which they are synthetically derived. Currently, SAF is approved as a blend of synthetically derived blend component and traditional fossil fuel.

Upstream of the SAF production process therefore incorporates renewable feedstocks: vegetable oils, animal fats, algae, alcohol and sugar derivatives, and even waste streams. Their path to flight starts with processing of the feedstock to an intermediate bio- or syn-crude, then proceeds with refining of that crude, followed by distribution to the airports. The level of pollutant emissions generated by consumption of the jet fuel, on a life cycle analysis basis, can be up to 80% lower with SAF than Jet A or Jet A-1. The feedstock generation, production, and distribution process to produce SAF is where the most carbon footprint benefits are realized.

Currently, there are seven types of certified "drop-in" SAF, which are readily available at some airports (e.g., Los Angeles, San Francisco, Oslo, Stockholm) and have already been used for over 300,000 commercial flights (blended in small percentage with Jet A or A-1 fuels). This accounts for less than 1% of global aviation fuel consumption, which is why a push towards the adoption of sustainable aviation fuel is increasingly desirable. In fact, according to studies in the ATAG’s Waypoint 2050 report, growth in use of SAF at the current rate would only yield 2% of global fuel consumption by 2025.

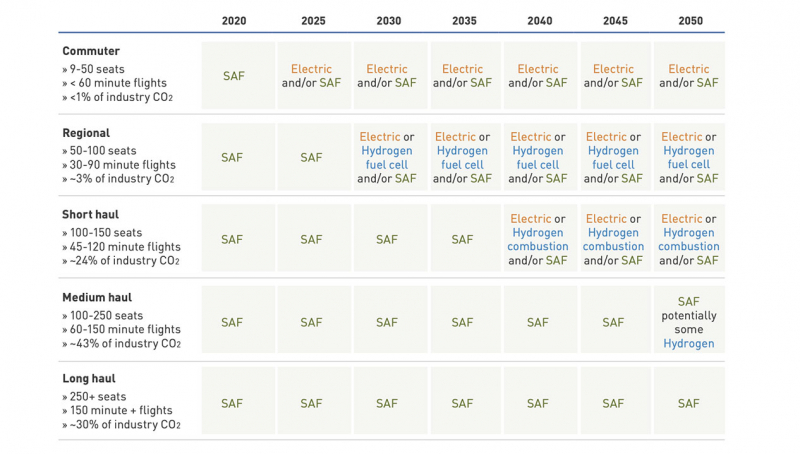

The same report also shows that displacement of traditional jet fuel could reach 86% of the global fuel supply (450-500 million tons) by 2050 with new investments, regulatory policies, and increases or optimizations in SAF production and their supply chain. In addition, according to industry studies, if we add the contribution of completely new technologies (such as hybrid electric or hydrogen), the sector would be able to reach the much-desired goal of zero carbon emissions by 2065.

Hydrogen could also be another renewable fuel solution, although much time is yet needed to allow its use. For example, liquid hydrogen requires cryogenic fuel tank storage and delivery systems, and even aircraft fuel tank capacity will need to be quadrupled since liquid hydrogen requires four times the volume per unit energy as the Jet A/A-1 fuel. Thus, for transoceanic or intercontinental flights, SAF solutions could be the only one that is likely to be adopted in the next few decades, given the time required for the development and technological maturity of innovations for wide body (150 to 400 passengers) aircraft.

This is one of the reasons why GE Aviation has been among the industry leaders involved in the renewable fuels testing and certification process since as far back as 2006. In fact, all GE engines are certified to use Jet A and Jet A-1 fuel, and as a result, are equally capable of operating using SAF that meets the same requirements specified in ASTM D1655 and D7566 standards. As Dr. Gurhan Andac, GE's Engineering Leader for Aviation Fuels and Additives, confirms. "SAF allows a more sustainable production and distribution process - that is consistent with economic, social, and environmental goals – along with an ecological balance as it mitigates consumption of natural resources and contribution to climate change, reducing aviation’s carbon footprint."

For more than a decade, GE Aviation has been focused on the performance and effectiveness as well as the qualification of SAF so that their use guarantees performance that is equivalent to, or better than, that obtained by using traditional fuels. "Our teams ensure that the use of SAF does not adversely impact the engine system and its components, thanks to vigorous testing and analysis activities during evaluations," continues Andac.

"We are also strongly engaged with the industrial and governmental organizations and committees that have the task of maintaining and developing SAF and related standards both on an operational level, and regarding policies and regulations that help the transition from conventional to more sustainable fuels; not to mention, also with customers who want to use them and make the transition."

"We are strongly engaged with organizations and committees that have the task of maintaining and developing SAF and related standards both on an operational level, and for their policies and regulations that help the transition from conventional to more sustainable fuels"

Such transition presents several complexities, including the comparatively high product and process costs and challenges around the infrastructure and supply chain, which is still underdeveloped and not widespread around the globe. "Along with research and development, policy and regulations are needed to advance the technology to reduce the cost, and to establish robust infrastructure and supply chain: such efforts are required to reach a future state where SAF could be used without blending it with the conventional fuel" says Andac’s European colleague Antonio Peschiulli.

Peschiulli is the Combustion Technology Engineering Leader at Avio Aero, and since 2009 (within the laboratory shared with the Politecnico di Torino, called GREAT Lab – GReen Engine for Air Transport), he has also dedicated himself with his colleagues to comparative studies of traditional and alternative fuels with the relative effects on the aircraft engine influenced by the nature of the raw material on which the fuel is based. Peschiulli's commitment to sustainable aviation programs also developed subsequently with Clean Sky2.

"Policy and regulations are needed to advance the technology to reduce the cost, and to establish robust infrastructure and supply chain: such efforts are required to reach a future state where SAF could be used without blending it with the conventional fuel"

From the experienced point of view of those who design components such as aeronautical combustors (clearly central to the adoption of SAF), the issue becomes more complex: "in a sector as regulated and high-tech as aeronautics, on the one hand, aviation design applies stringent standards to fuel properties to ensure safe operation of the combustor, and on the other hand, the process of certifying the fuel itself ensures that it - whatever the raw material or production process - continues to comply with those requirements," Peschiulli explains. “It needs work to ensure that SAF-fueled jet engines can operate at the same safety level of the ones using conventional fuel, gaining more experience than that we have nowadays.”

"Surely" adds Peschiulli, "in addition to the issue of costs an ethically sustainable production is also key: indeed, the production process of those SAF obtained from vegetable oils and related cultivations must actually respond to sustainability criteria including social-economic impacts, in favor of the global environmental protection and food needs.”

Cover image by Margherita Fruscoloni Morello