Invent

A 360° view on sustainability

While products and technologies are developed for flight decarbonization, Avio Aero is following in the steps of GE Aerospace to take on the carbon neutrality at its operating sites.

Feb 2023

Work is being carried out at factories, production facilities, laboratories, offices and sites worldwide to advance our goal to achieve carbon neutrality by 2030, with investments in efficiency, elimination of waste and lower-emission energy sources.

This is GE’s commitment to its operations - as it was announced three years ago and has involved all its businesses – and this momentous challenge clearly includes Avio Aero locations and its factories in Europe.

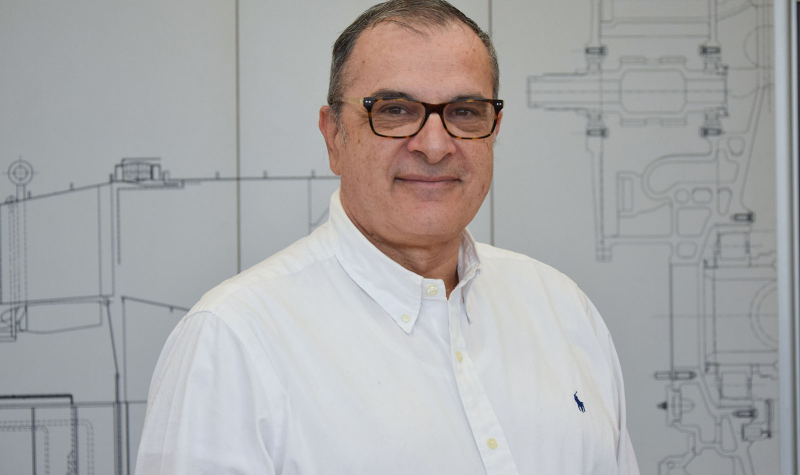

Specifically, the Polish, Czech and Italian sites have a key role to play in the total emissions of GE Aerospace, as explained by Massimo Silvestrin, an electronic engineer who, during his 33-year career at the company, has worked in industrial technologies, aeronautical production (for a long time) and, in the last 19 years, company infrastructures.

Today, Silvestrin is the Facilities Leader at Avio Aero, working alongside the teams at the several buildings and areas of the plants where almost 6,000 people are employed. “Our team coordinates with the GE Aerospace sustainability team that is leading the way towards our goal of carbon neutrality by 2030, with the primary goal of reducing CO2 emissions at our plants,” Silvestrin said.

"This is intensive work, it requires all company departments to help collect ideas and identify and implement measures, as well as guide conduct and investments or operations that affect energy consumption”

The work of Silvestrin and the teams at each Avio Aero site – where there are appointed energy focals, who are professionals responsible for periodically implementing and reporting activities and measurements aimed at the energy efficiency of plants and buildings – is coordinated with the central team in the United States, thanks to an exchange of information and practices.

Silvestrin explained: “this is intensive work, since it requires all company departments to help collect ideas and identify and implement measures, as well as guide conduct and investments or operations that affect energy consumption.”

Individual behaviors, according to Silvestrin, are essential to achieving goals. “Even the most efficient systems or the most technologically advanced LED lamps still need to be used with the right mindset to produce the maximum benefit.” It is for this reason that a group of employees at Avio Aero carry out awareness-raising activities and propose periodic initiatives aimed at improving behaviors, habits and, above all, consumption.

The desire for “virtuous consumption”, however, must go hand in hand with technical expertise and a systematic, professional approach to efficiency and emission reduction solutions: such as the installation of photovoltaic panels (which is planned this year n Brindisi), the more widespread use of LED lamps, the implementation of sensors to avoid waste, and the optimization of heating and air conditioning systems.

“All areas and processes can potentially be improved,” Silvestrin added, explaining what is currently being done. “For example, with regard to our production plants and machines, we have installed inverter motors and sensors that allow the machines to use only a minimum amount of electricity during periods of inactivity. We now also use variable speed compressors to optimize consumption in relation to workloads. These are solutions that we keep on implementing across our plants”.

As for the technical approach to efficiency, the Facilities team has begun analysis of the most energy-intensive systems: typically, these are compressed air and chilled water production plants, the heat treatment areas of the factory.

“In each case, all ideas that can help reduce emissions or waste are evaluated and implemented. Consumption before and after the introduction of each action is measured, using indicators and KPIs when these are available in the factories, or carrying out precise measurements where they are not. These are practices that we routinely define and share with the central sustainability team,” says Silvestrin.

"Our carbon neutral target requires a global team working together and sharing best practices, Avio Aero is helping lead the way with its focus on improving energy efficiency in their operations to rise to this challenge"

The global leader who follows the teams at GE Aerospace plants around the world has a holistic view of the challenge undertaken. “Reaching our carbon neutral target requires a global team working together and sharing best practices. Avio Aero is helping lead the way, with its focus on improving energy efficiency in their operations to rise to this challenge”, said Geraldine Barnuevo, GE Aerospace Sustainability Leader.

The challenge is certainly shared by every industrial sector, in Europe as elsewhere. “In my opinion, the key lies in the mindset of each individual, and therefore in the consistency of behavior to minimize energy waste, such as with the implementation of processes and use of technologies that consider the environmental impact from the start. Neutrality comes at a cost which is not always offset by immediate benefits. And the cost to remedy the damage done in recent decades is getting greater, we need to act immediately,” Silvestrin said.

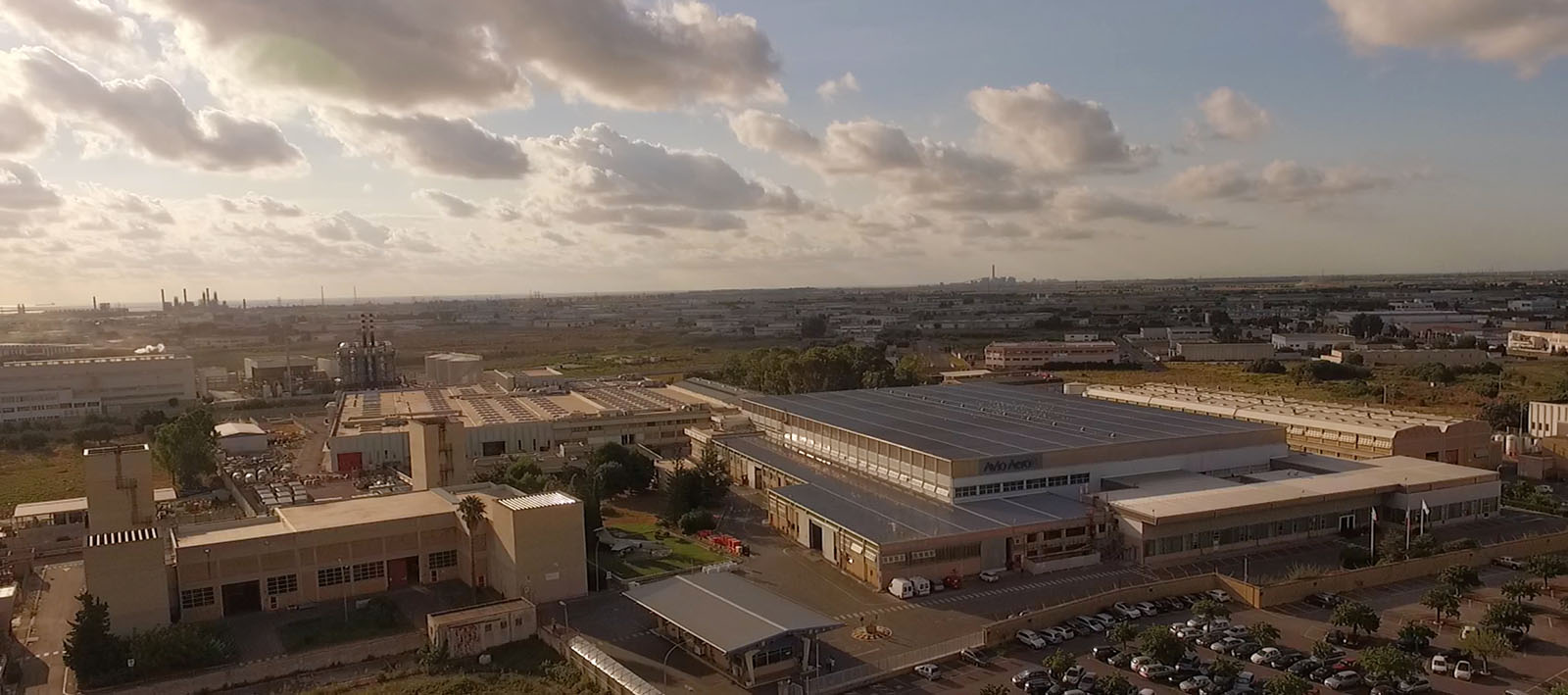

Cover image: aerial view of the main Avio Aero Italian plant, in Rivalta di Torino.