Invent

Champions of technical talent

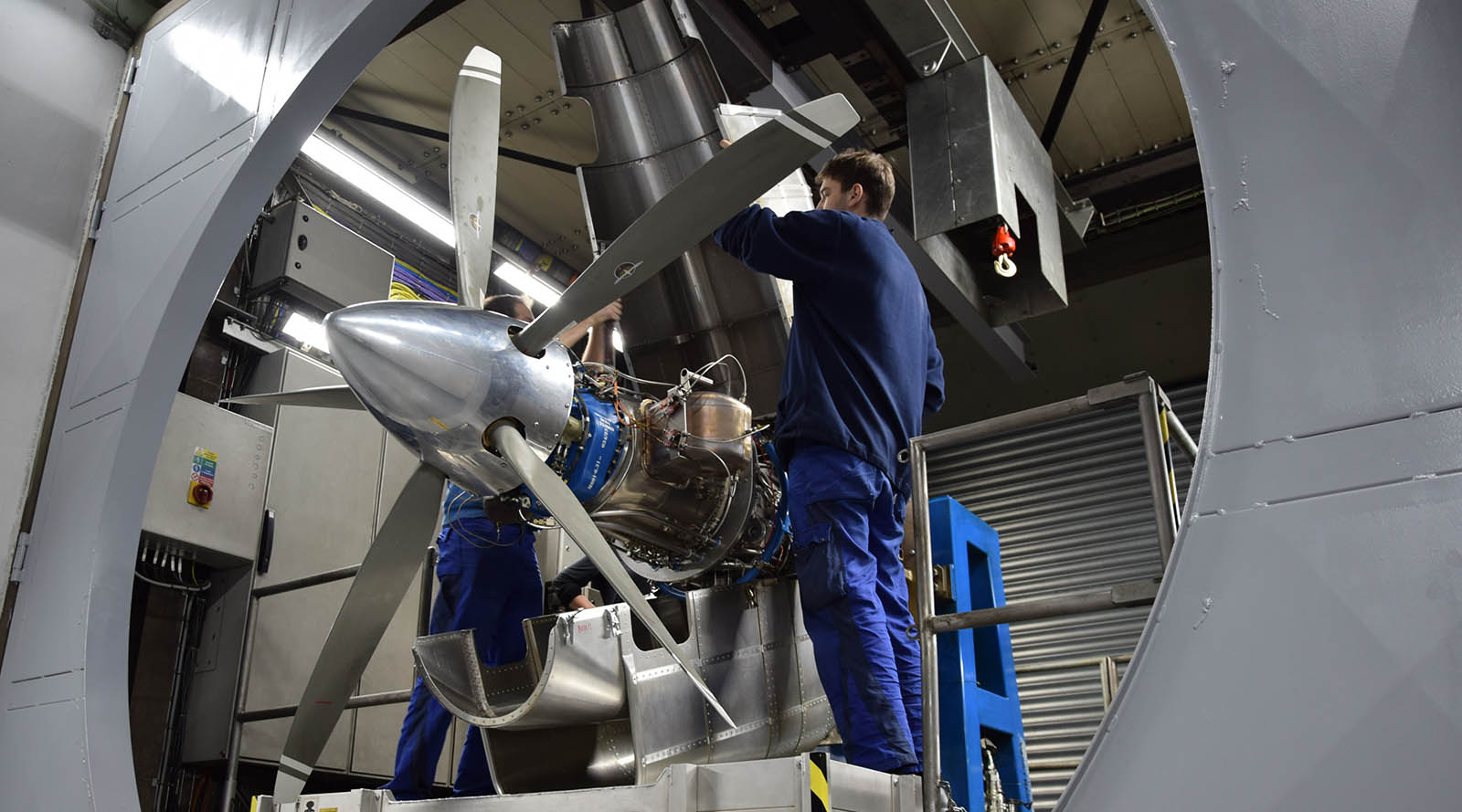

Beyond and after design, there is a world of processes and technologies that requires a holistic vision and great ingenuity, as the expert production engineers can tell us.

Jul 2024

Just three years ago, the role of production engineers and controlled title holders (CTH in short, who are production engineers specialized in technical disciplines) started to grow along with planned and structured career paths, expanding their influence and -impact at Avio Aero. Both regarding the introduction of new products for aircraft engines and for existing products, these professionals are at the same time able to innovate and consolidate the way of designing and optimizing, at a technological and organizational level, production processes.

To date, there are about 300 production engineers at all levels in Avio Aero and, together with them, the leading roles of Chief Manufacturing Engineers have increased from just one (three years ago) to seven: a growth that has reached the entire product and technology portfolio of the company, which today can count on a substantial number of professionals who are highly trained in products and processes.

The main goal of these professionals is "to be able to efficiently industrialize increasingly complex aeronautical components both in terms of geometry and materials to achieve increasingly better and more sustainable engine performance," explains Dario Mantegazza, Chief Additive Manufacturing Engineer at Avio Aero. "This goal can be achieved by possessing and developing high-level technological skills focused on specific issues, which are cultivated and protected not only in the field of design, but also in production".

These professionals are closely linked to those typical of design but have their own uniqueness and global reach in GE Aerospace. "Manufacturing engineers play a critical role in translating design into product, ensuring the manufacturability of parts in new products, developing manufacturing processes for production, change management and deployment of technologies," explains Vinod Kumar, Chief Engineer of Manufacturing at GE Aerospace. "To do this, they use Flight Deck to develop standard work, contribute to daily management and actively engage in problem solving thus helping the factory achieve its targets. In addition to above, the CTHs are also recognized experts in the company and in the sector, bringing strong technical excellence focused on product quality, process rigor, technology maturation and external partnerships".

Kumar has a 25-year career at GE Aerospace and Global Research, spanning a variety of roles ranging from traditional manufacturing processes to innovative and specialty manufacturing processes, automation, and technical talent development. Today, he is responsible for promoting standards, improving technical rigor in manufacturing as well as technology maturation and adherence to quality requirements together with his team of Chief Manufacturing Engineers and CTHs active in the various global sites.

"CTHs are champions of technical talent, mentoring aspiring CTH candidates and ensuring the appropriate technical capabilities exist in production within our locations. With them, all manufacturing engineers have a huge opportunity for growth, as they help make GE Aerospace a world-class leader in our industry," says Kumar.

In a technology company, engaged in a critical and highly regulated sector such as aviation, it is necessary to grow an ecosystem in which these unique roles interact with an overall vision capable of connecting processes (thanks to a vertical and in-depth knowledge of the process, as in the work of CTH) in order to create a safe product, conforms to the design, respectful of time and costs.

"Especially when new products or technological solutions are introduced," continues Mantegazza, "the contribution of Chief Manufacturing Engineers and CTH becomes crucial in the work with other functions. As well as in continuous improvement and problem solving, typical of our Lean culture. The Chief Manufacturing Engineer supervises processes crucial to the success of a product, also dealing with the growth of talent, the strategy of technological evolution, supporting the achievement of delivery and cost targets, evaluating the maturation and readiness of new products inserted in such a complex market".

Looking at individual careers, all these aspects and interactions emerge clearly: Maria Rita Petrachi, for example, started in 1996 as a specialist engineer in maintenance and repairs for aircraft engines, becoming Technical Leader, and then for a further ten years from 2009 she was involved in research and development (promoting the birth of a European network of collaboration that is still active and growing). Today, Petrachi leads the introduction of new service processes, is CTH of Repair Services and coordinates the 'community' of Avio Aero CTH active in the Repair field, maintaining frequent contacts and synergies with the corresponding global community managed by GE Aerospace.

"I believe that for a role like this, in addition to the technical aspect, the type of systemic approach is a winner"

"In this role, I find it stimulating to be able to face new challenges that always bring with them opportunities to learn both from a technical point of view and from that of interpersonal relationships with external realities," says Petrachi. "I think that my professional path has allowed me to learn different disciplines and also given me the opportunity to develop an all-round knowledge that now allows me to approach work with a systemic approach and guide the team towards solutions. In general, I believe that for a role like this, in addition to the technical aspect, the type of approach is a winner."

A business ecosystem that faces the complexity and changeability of the modern industrial scenario by focusing on collaboration between the best skills to be successful. "The company is continuing to invest and expand this structure made up of CTH within the production teams in all its locations," says Mantegazza, "comparing it with the corresponding figures in GE Aerospace and with the support of Leadership. I believe that this will allow us to be increasingly efficient, productive and therefore competitive on a global scale".

And while eleven new CTHs have been announced at Avio Aero and will join the production teams at each European location, on the other side of the Atlantic Vinod Kumar envisages the same vision: "These career paths are suitable for those who want to be technical experts and who are determined to build and master high technological skills for the benefit of the entire company. They are considered pillars in the organization because they support a wide range of activities, with particular attention to increasing and sharing Avio Aero's industrial technological know-how, aiming to meet the highest quality and on-time delivery to our customers, without any compromise on product and process safety."