Future

From hybrid electric to hydrogen and vice versa

In Turin, kickoff events for the AMBER and HYDEA projects with Clean Aviation saw partners come together to start development work for the European aviation of tomorrow.

Mar 2023

The subalpine city that has been home to the automobile industry for decades is increasingly looking to the sky and the aircraft that fly through it. A few months after the most recent Annual Review event held in Turin, last summer, Avio Aero’s engineering department once again hosted the Clean Aviation teams and the members forming the consortia of two of the five European projects that Avio Aero has been awarded with. The two projects that it directly coordinates are AMBER and HYDEA.

The goal of the two kick-off events was to initiate the research and development work that will lead to the demonstration of key technologies aimed at enabling reduced CO2 emissions in aviation: in the hybrid electric field for AMBER and with direct hydrogen combustion for HYDEA.

“The challenges in front of us present a high level of technological complexity. These days working together as a team have given us further confidence on the expertise and skills of the members of the two consortia. The active participation and interest shown by representatives of the Clean Aviation Joint Undertaking constitutes an added encouragement,” said Andrea Milli, Clean Aviation Senior Technical Program Manager for Avio Aero and GE Aerospace.

The two events, each lasting two days, saw industry players including aircraft manufacturers Leonardo and Airbus, small-medium enterprises, research centers, and European universities joining forces to offer diverse visions, approaches, skills, and technical backgrounds. A total of 21 members are working on AMBER and 29 members are working on HYDEA.

“It’s a very diverse pool of partners, which is a hugely important aspect when you look at the vast industrial experience that runs through the network,” Milli says. “It becomes even more important because of the broad technical content of the two projects and the level of technological maturity we want to achieve.”

Although AMBER and HYDEA are each based on a distinct main propulsion solution, both are exploring the use of hydrogen with two different technological approaches. Such commonality is also highlighted by Dr. Jean-François Brouckaert, Head of the Technology Office of Clean Aviation, the European Union’s research programme that has recently launched their 2nd call for proposals to submit yet more new projects devoted to decarbonization.

"A very diverse pool of partners becomes even more important because of broad technical content of the two projects and the level of technological maturity we want to achieve”

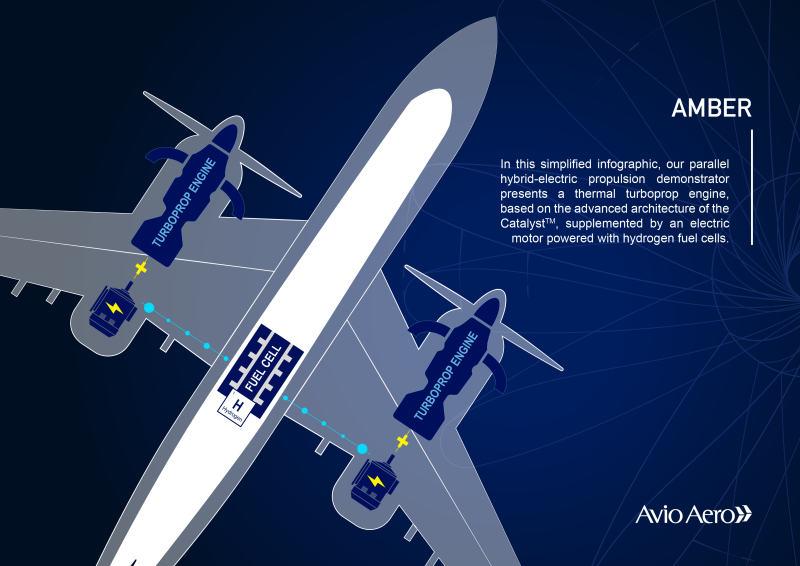

“HYDEA, by developing technologies to power gas turbines (turboprop or turbofan) with hydrogen instead of standard fuel, will make it possible to cut CO2 emissions and assess the level of NOx emission reductions. On the other hand, AMBER aims to create a hybrid-electric engine that runs in parallel by hybridizing a conventional turboprop. While an electric motor is powered by hydrogen fuel cells, the gas turbine can use sustainable aviation fuel (SAF) or hydrogen as well, but in the longer term” Brouckaert explains.

According to Brouckaert, AMBER best matches the ambitions of Clean Aviation essentially because it aims to reduce pollutant emissions in three ways: “by improving total engine efficiency, by using alternative fuels such as SAF or hydrogen, and by electrifying the engines.”

“For the AMBER project, it will be critical to keep this dual activity well-coordinated,” Milli explains. “That is, activity related to propulsion technology and activity related to aircraft design, in order to make sure that there is continuous integration between these two work streams.”

Indeed, the architecture Milli and his colleagues have in mind is particularly challenging. “At the heart of the demonstrator is the integration of electric and mechanical machines, in order to produce the parallel hybrid-electric architecture we have envisioned. Then there is the integration of fuel cell and electric machine, i.e., the most innovative core of the architecture which enables zero-emission power generation. Meanwhile, the definition and management of the thermal system will also be crucial. The whole thing will then have to work in parallel with an advanced turboprop, such as our Catalyst, and finally be integrated on the aircraft, which will also need to be equipped with a digital control system to govern all this architecture.”

AMBER proposes a safe and reliable hybrid-electric propulsion solution, according to Brouckaert: “the traditional gas turbine of the turboprop engine is supported, and hybridized, by an electric motor powered by fuel cells using hydrogen. The advantages are first in fuel cells, which eliminate CO2 and NOx emissions, as well as particulate matter and sulfur dioxide.”

The connecting element between AMBER and HYDEA is therefore hydrogen. “Looking at how to incorporate the use of this element in aviation is in itself a mammoth step from a functional and technological point of view. There a many complexities, the first being safety: both in combustion and storage. Support from authorities such as EASA will be critical, both to integrate it on the aircraft of tomorrow and to regulate it,” Brouckaert says.

Developing an engine system that revolves around hydrogen requires specific skills provided by the technological diversification of the project partners, which bring solutions directly impacting emissions. “For example, the design of the combustion chamber in order to ensurethe lowest level of NOX emissionsis an important research topictoday in the world,” Brouckaert continues.

The impression of the endeavor’s scale is the same in those personally involved in the development, such as Milli: “HYDEA’s achievements could revolutionize our industry. Direct combustion of hydrogen in an aircraft engine could enable future commercial fleets to reduce emissions by up to 70%, which is a huge potential. Developing a combustion system that works and performs like a traditional one but using hydrogen is the key challenge. As is the cryogenic storage of this element, which also significantly impacts the design of the aircraft and the engine and aircraft certification process.”

HYDEA’s mission for Clean Aviation is to demonstrate the feasibility of using liquid hydrogen as a fuel in aircraft engines. This is why Brouckaert recommended that the members of the two projects – highly specialized organizations and institutionswith varied expertise and technological resources - should cooperate and coordinate as best as they can, to deal with “complexity of considerable magnitude”.

“We are in an era that is leaving behind the classic separation of engineering disciplines as far as aircraft design is concerned"

“We are in an era that is leaving behind the classic separation of engineering disciplines as far as aircraft design is concerned: electric systems integrated with gas turbines, liquid hydrogen tanks, on-board high-voltage systems and complex thermal systems. Dedicated instrumentation and systems are needed to test and develop all this. A certain chemistry between the partners makes all this possible. Complex design problems, such as those related to weight and volume, can thus be overcome. Vast exchange of experience and constant discussion, especially with those involved in integration on the aircraft, are the key to success for Clean Aviation projects.”