Invent

A Catalyst Carol

The first European-born GE engine has achieved another crucial step, once again during that time of the year, ahead of its upcoming first take-off for flight testing.

Jan 2021

The European engineers and technicians who relentlessly - and today with even more enthusiasm – are progressing, between Prague and Berlin, over the operational and testing activities for the new GE Catalyst, have once again celebrated the new year achieving important advancements for the engine’s program.

It was the evening of 23 December 2017, when the roar of the new turboprop engine rang out between the walls of the test cell of the GE Aviation Czech plant in Prague: at that time, dozens of Czech, Italian, German, Polish, Spanish and French professionals had their eyes glued to the screens of the control room connected to the nearby test bench on which the Catalyst - designed and developed from a clean sheet only a couple of years earlier - was fired up for the very first time.

Exactly three years later, the special coincidence. Last December 18, at the Berlin airport - where the Beechcraft King Air test aircraft is located and on one of its wings the new Catalyst was installed in order to fulfill flight tests through 2021 - the engine was lit for the first time on wing in its natural habitat; the runway. The start of ground testing marks a new phase that is even more intense and concrete, because now the engine and the propeller form a whole with the aircraft, connected to the controls that the test pilot will operate.

“The engine started flawlessly on the first attempt”, says David Kimball, Catalyst Product Line Leader. “It reached ground idle in a stable and predictable manner without any intervention, and the fully integrated engine and prop control system worked seamlessly. This not only demonstrates progress within the program, but also showcases the versatility of this engine: the Catalyst can be installed in a wide spectrum of aircraft applications with vastly different technical architectures.”

In the last three years, the combined operations of all types and intensities on 13 assembled engines and their components have well exceeded 2,000 hours of duration. From the altitude chamber tests (in which the Catalyst set the record for its category hitting 41,000 ft), to the icing test carried out even in Canada, to fatigue, vibration, ingestion tests up to digital simulation tests for the FADEPC (Full Authority Digital Engine and Propeller Controls) in the avant-garde Wet Rig at Avio Aero Brindisi.

During this short time - although extremely full of validation activities, data and results collection - all the new technologies on board the Catalyst engine have already shown what they are capable of: the first turboprop ever with 3D printed parts, an industry-best 16:1 overall pressure ratio, in addition to the achievement of higher-than-average cruises in the same class, with a 15% reduction in fuel consumption, 15% lower CO2 emissions and up to 24% less NOx emissions.

"We are running various power management scenarios to verify the engine’s performance, operability, and responsiveness to the FADEPC enabled pilot inputs from a customized cockpit... our general objective is to assure the Catalyst is ready to fly"

Today, the team is continuing with the ground test campaign. “Nest steps are to clear the engine for aircraft taxiing,” says Jiri Pecinka, a GE Aviation Staff Test Engineer. “We’ll accomplish this by running various power management scenarios to verify the engine’s performance, operability, and responsiveness to the FADEPC enabled pilot inputs from a customized cockpit. During the ground taxi campaign, we’ll also validate the engine’s installation effects which is critical as we prepare for first flight. Our general objective is to assure the Catalyst is ready to fly!”

Catalyst is even a more eco-friendly turboprop engine, benefitting from the largest research and development program for sustainable for sustainable aviation advocated by the European Community through the Clean Sky2 Master project and presenting technological contributions that were not only coming from the excellence of GE specialized centers such as the Aviation Advanced Technology of Munich, the Engineering Design Center of Warsaw or the dedicated teams of the Italian engineering Avio Aero. But such contributions have been supported by the collaboration network with universities and institutes among the most renowned in Europe and the most coveted between professionals and young engineering talents.

Strongly concrete collaborations, which go beyond scientific, technical or intellectual exchange, because they come to touch and test real components and engines made up of metal, circuits, oil and fuel inside shared facilities. An Italian example is the partnered laboratory between Avio Aero and the Polytechnic of Bari, where the FADEPC was born, whilst an even larger example is the partnership between GE Aviation Czech and the famous Prague’s Czech Technical University, CVUT. Based on advanced and experimental testing, the Czech university-industry partnership is physically represented by four test cells for engine testing and even a small private airport (namely that of Hradec Králové) that will welcome it again.

Just 10 days before the start of ground testing, the European team based in Prague used one of these cells – located nearby the GE Aviation Czech plant – to successfully complete another crucial testing on the so-called Core2 engine. Another essential achievement towards the flight-testing campaign as confirmed by the tens of engineers who worked for this results in the last four years. “In short, we basically transformed a turboprop in a turbojet to run these tests,” says Stefano Renna, Catalyst Model Engineers Leader at GE, “focusing on the core components and applying over 800 sensors all around them, even onto the rotating ones. Only this huge and delicate instrumentation work took a couple of years to our team”.

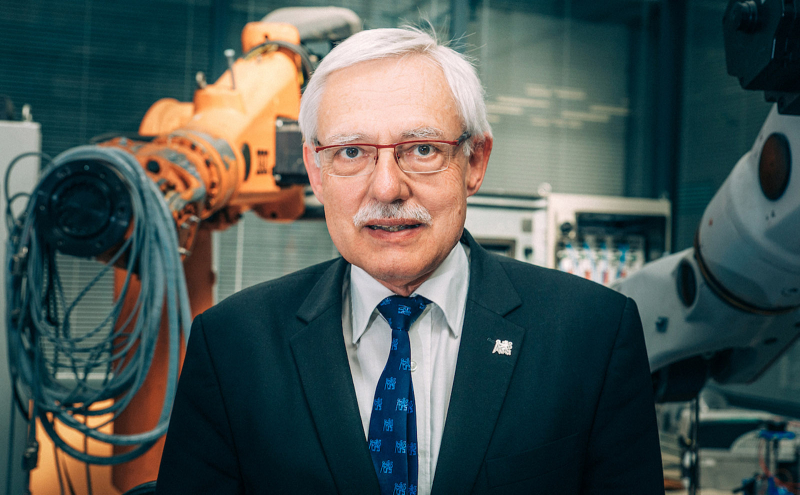

Such testing activity - which has been extremely complex and allowed the collection of tons of key data even straight from those parts of the engine that can reach 49,000 rpm - has been possible thanks to the cooperation between the GE Aviation Czech team and the Prague University. “I am personally amazed by the work done with GE” said the dean of CVUT, Michael Valášek. “The design of engine installation on wing generated already tons of learnings for high-talented students we’ve selected to join such opportunity within aviation, and our team’s just looking forward to the upcoming in-flight experiments as we’ll harness that experience too for the work we’re carrying-on to develop a model for preventive maintenance of modern turboprop engines, like GE’s Catalyst.”

"We receive great support from the GE Aviation team, it helps us develop the right expertise at the university and enable us to grow the next generation of engineers and leaders that will likely develop the next generation of aircraft engines"

The partnership between CVUT and GE Aviation Czech, strong of its capacity and capability, is yet making more and more Czech Republic an attractive destination for high-end R&D activities in the aeronautics field as well as for young European students who continue to choose Prague for their educational path. “We receive great support from the GE Aviation team, it helps us develop the right expertise at the university”, adds dean Valášek, “enabling us to grow the next generation of engineers and leaders that will likely develop the next generation of aircraft engines!”

*The team photo has been taken without face masks only for the instants of a single shot, as per WHO outdoor contagion guidelines.