Future

Reliable performance for the RACER

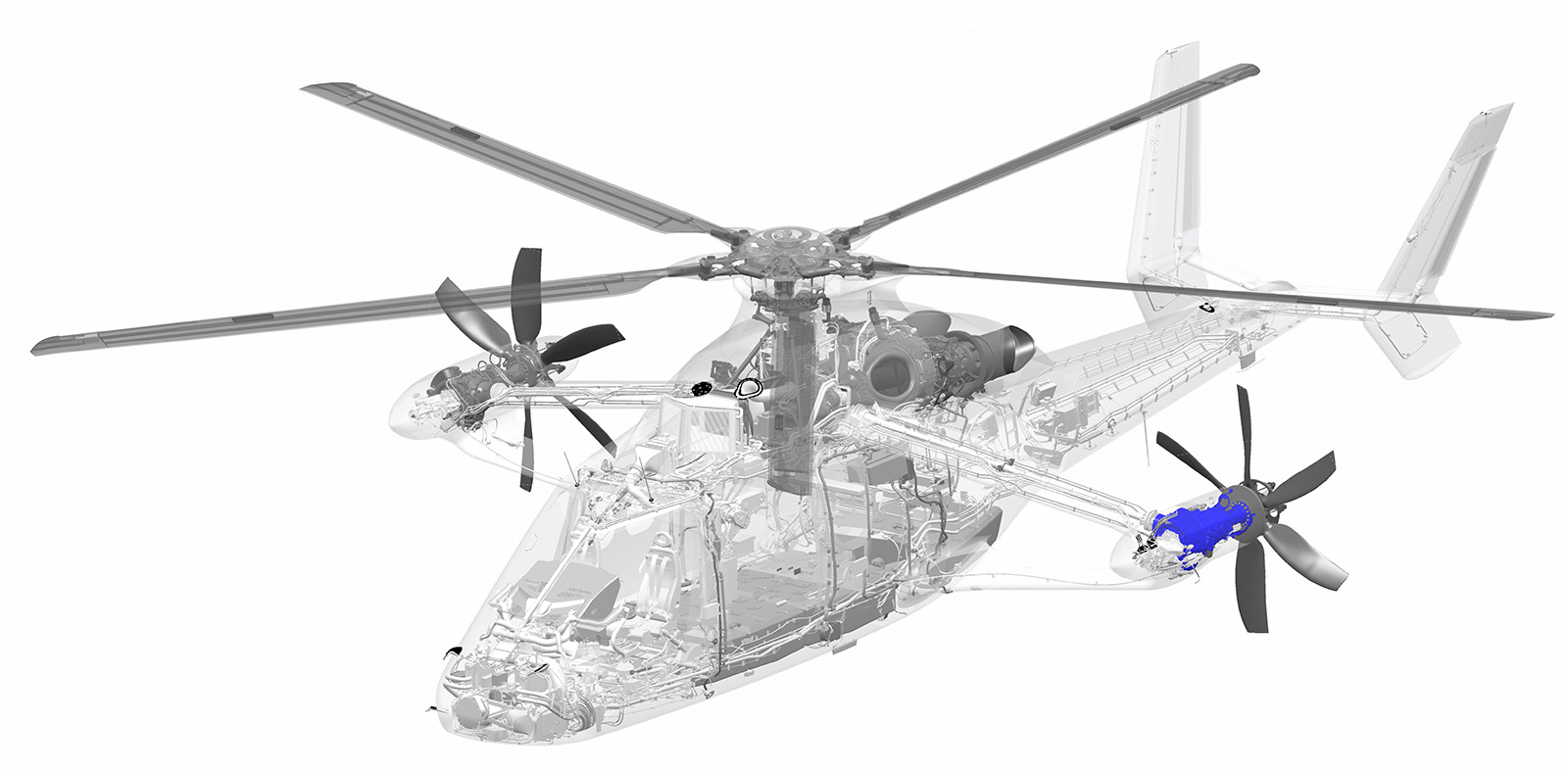

Intensively crucial tests have been successfully completed on the drive system that operates the lateral rotors of Airbus Helicopters' technologically advanced, futuristic aircraft.

Feb 2023

Anyone interested in the current state-of-the-art of European helicopters can rest assured: the RACER aircraft by Airbus Helicopters is ahead of any other aircraft in its category when it comes to the future of short-to-medium-range flight, such as travelling between different parts of large cities (for instances, megacities inhabited by 5 million people and more).

Avio Aero has been a partner in the programme since the beginning, working alongside the world's leading helicopter manufacturer. It is taking an active part in the construction of the very first example of this impressive aircraft, capable of reaching a cruising speed of 400 km/hr, and with a range of over 400 nautical miles. The first flight is expected to take place within the year.

Avio Aero designed and custom-made various parts for the RACER, including the lateral gearboxes (LGB): drive systems able to spawn 1MW of power, and constructed using cutting-edge materials and processes.

As Marinella Marconi, Racer Technical Leader at Avio Aero, explained: “The LGBs are made from an innovative alloy, whose special chemical composition gives them higher wear and temperature resistance. The LGB bearings are hybrids, they are fitted with steel rings and involute parts made from a form of ceramic. This material offers several benefits, including better performance in the event of poor lubrication - thanks to its low friction coefficient - and greater lightness when compared to steel.”

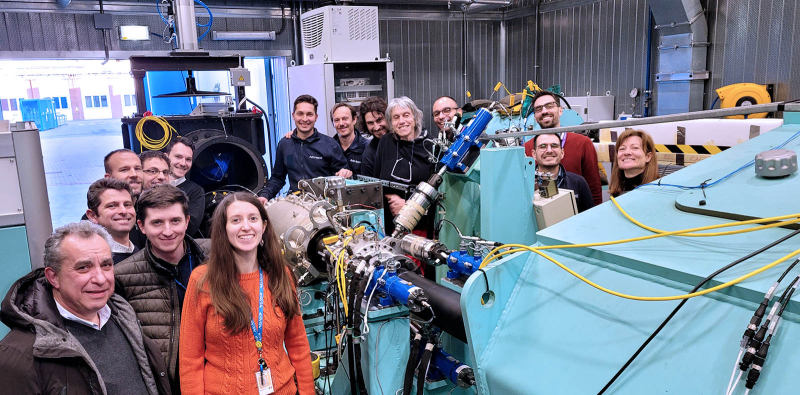

Last summer, the engineering, testing, research and manufacturing teams at Avio Aero's Rivalta di Torino plant, at Sangone Test Center (Italy) and at Bielsko Biala (Poland) began an intensive campaign of tests. These included testing the mechanical and fatigue resistance, the oil system, and more generally, the performance of the lateral gearbox.

Michele Fantetti, leader of the Sangone Experimental Laboratories, provided more details: “for the mechanical endurance test, we explored all the possible flight conditions set out in the aircraft specifications, and finally inspected the components to check their condition and ensure they reached the level of reliability required for the gearbox. After the module was reassembled, we continued with the fatigue and oil-off tests, setting up brand new systems and purpose-built benches for testing these products.”

In particular, the oil-off test is a source of pride for the experts at Avio Aero. This test for the gearbox passed with flying colours: it is a basic test, which, given its critical nature, is typically carried out by the helicopter manufacturers themselves. It simulates an emergency mission, and so allows one to test the safety of the aircraft to the full, demonstrating that (even in unfortunate eventuality of lack of oil) maneuverability, and therefore the possibility of landing safely, is guaranteed.

“This also gives the pilots a certain margin of choice on the landing site, a decisive element in extreme conditions. It is a certification test that becomes more or less demanding depending on the size and type of aircraft,” adds Marconi. And the RACER, with its distinctive shape halfway between a helicopter and a plane, is quite a remarkable size.

The RACER is a Clean Sky 2 project, forming part of Europe's largest research and development programme focused on decarbonization It is the first full-scale demonstration model to feature helicopter drive systems for a new generation of engines, built with the use of unique materials and technologies: ceramic bearings, special gear alloys and a heat exchanger made in additive manufacturing. This process allowed greater design freedom, so the heat exchanger is very well integrated and compact in relation to the gearbox and is made up of a smaller number of parts.

The fatigue tests also produced very impressive results. Indeed, they enabled an over-torque of more than 130%, demonstrating the resistance of the teeth in the individual gears of the transmission system.

The series of tests concluded at the end of January relate to the drive system for the right wing of the RACER, with estimated completion at the end of August. At that point, the second LGB will also be given permission for the inaugural flight, which promises to highlight all its qualities in terms of high performance and reduced emissions, resulting from its advanced technological content.

The teams at Avio Aero and Airbus have collaborated in a very positive way in the face of unprecedented complexities, increasing their level of trust together with their level of technological expertise. A test campaign of this nature on a unique aircraft came with no past practice or reference points.

"The expectation at Airbus Helicopters, and indeed of all our teams, is that this aircraft will provide better levels of performance and emissions”, as Gian Mario Bragallini, Head of the New Product Development team in the engineering department, pointed out.

“We spent a lot of time working alongside our counterparts at Airbus, going into every technical detail. The level of expertise and skill that we have gained from this project counts as a major success, and it has shown how close collaboration between companies, in this case aircraft manufacturers and engineers, can indeed make a huge difference.”