Aviation

Our rotating wing world

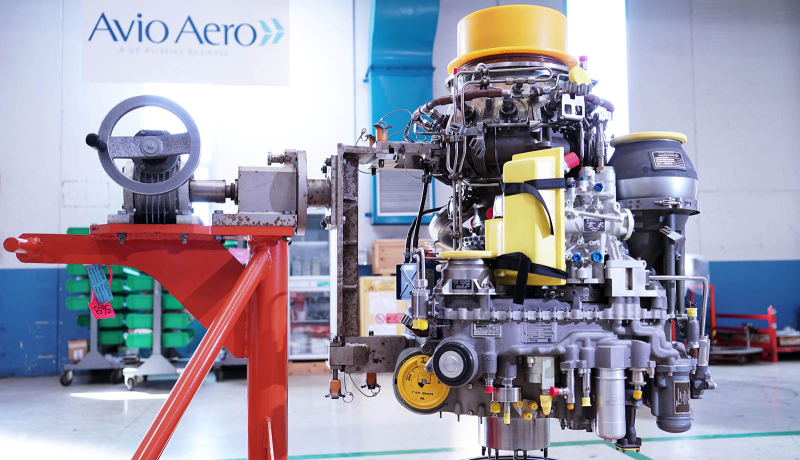

Avio Aero has been offering helicopters’ engines, transmissions and service for more than 50 years and today is looking ahead with real ambition to expand in this market segment.

Aug 2022

Avio Aero's history in the helicopter world began in the 1960s, when what then was Fiat Aviazione started the design and production of main transmissions for the then Aerospatiale helicopters.

Starting from the 1970s, the company's interest in the helicopter market shifted towards the engines, thanks to collaboration with GE Aviation on the T700/CT7 family of engines, universally recognized for their power and reliability, attested to by over 100 million hours in service, as well as by their use on such legendary aircraft as the Black Hawk and Apache.

Since that time, participation in the T700 program has grown to bearing currently approximately 60% responsibility for the design and production of the latest models of this turbo-shaft engine family, as well as the addition of a wide range of service and maintenance offerings.

Thanks to the role and experience gained by Avio Aero on the T700/CT7 family, use of these engines has been extended to numerous other helicopter programs: from the EH101 to the NH-90, the AW101 and the very recent AW249 attack helicopter.

"Our offer covers the entire engine life-cycle," explains Claudio Stefanelli, Military Technical Support Manager at Avio Aero, "in fact, after assembly and testing in our Brindisi plant, our Military Customer Support team also monitors customers after delivery. In addition, our experts also support test and acceptance flights for helicopters and carry out so-called 'on field' operations at airports or bases, and even offer training courses to Armed Forces specialists”.

In addition to technical and logistical support, MRO (Maintenance, Repair and Overhaul) is carried out at the Brindisi center of excellence, meaning all the repair and maintenance activities for engines returning from service to undergo scheduled or extraordinary operations, as well as implementing configuration updates.

"Many years working alongside our clients enable us to offer a comprehensive service in support of operational needs. Thanks to the experience and knowledge of our technicians, we have the ability to resolve any problems in a timely manner, ensuring the continued operation of engines and helicopters," ends Stefanelli.

By motorizing the AW249, which will be equipped with the CT7-8E6, the backbone of the Italian Armed Forces rotary-wing component will be equipped with engines from the same family. "The choice of the CT7-8E6 to propel the AW249 is key in completing the standardization of engines used on in-service fleets. Using the same engine family increases logistical commonality between fleets and enables increased operational effectiveness and optimization of maintenance costs to benefit helicopter efficiency," explains Francesco Manciagli, Military & Helicopters Sales Director at Avio Aero.

Starting in the mid-10s of the new millennium, Avio Aero decided to add transmission systems to its engine offerings for military or civilian applications, resuming and thus renewing the activity started in the 1960s and becoming the protagonist of successful programs such as AS365, AS330 and CH53E.

"The company has set itself the challenge of achieving the role of supplier and maintainer of helicopter dynamic systems in the marketplace, due to the expertise it has gained so far in power transmission and generation. The advent of hybrid and innovative architectures will increasingly blur the line between engine and aircraft expertise, and strategic partnerships with major and emerging helicopter OEMs are key in this regard," Manciagli concludes.

Within this framework, we should consider the participation in RACER, the hybrid architecture helicopter that Airbus Helicopter is developing as part of the Clean Sky2 initiative; and the more recent collaboration contract with Korea Aerospace Industries on the Surion program (the multi-role helicopter for which Avio Aero is developing an entire new drive system, by integrating it with the existing T700 engine).

"Being a key player in the development of the new transmission system of the Korean Utility Helicopter Surion offers two main benefits: the opportunity to relate with a high-level Industrial Partner such as KAI and the experience of engaging - for the first time as the system’s Design Authority - in the development and production of an entire system”, says Maurizio Faucitano, Helicopters Sales & Proposal Director at Avio Aero.

Benefits that thus evolve into professional and human advantages: "working alongside KAI engineers means activating a fruitful path, both in terms of culture and engineering, of discussion, exchange, that involves our people. A process," Faucitano continues, "that can only enrich our expertise and further enhance the international vocation that distinguishes our company and represents the common thread of all the successes achieved by Avio Aero in over 100 years of industrial history”.

"The successes achieved in recent years with programs such as VRT500, AW249 and Surion demonstrates a growth that we need to acknowledge and which translates into mastering new technologies while also remaining efficient, with the end result that our offerings become more competitive. Helicopter companies will be ready to engage us on the basis of our competitiveness, flexibility, skills and innovative capacity, whether they are established or emerging market players," Faucitano concludes.