Future

The green side of additive

An European research project that is heavily inspired by ecology and advanced manufacturing technologies.

Oct 2017

When it comes to European research projects, primarily in relation to Avio Aero, these are usually linked to the aerospace industry: for example, the renowned Clean Sky project. Looking beyond this, there is a huge European Union research program pursuing scientific excellence and industrial leadership through product and process innovation known as Horizon 2020.

Horizon 2020 is a research and development program through which Europe is trying to break through national barriers by sharing knowledge to enable environmentally-sustainable growth, and for this the EU has earmarked 80 billion euros over 7 years until 2020. This is the most important European program on an industrial level with the aim of facilitating access to technological innovation for all companies, regardless of their size.

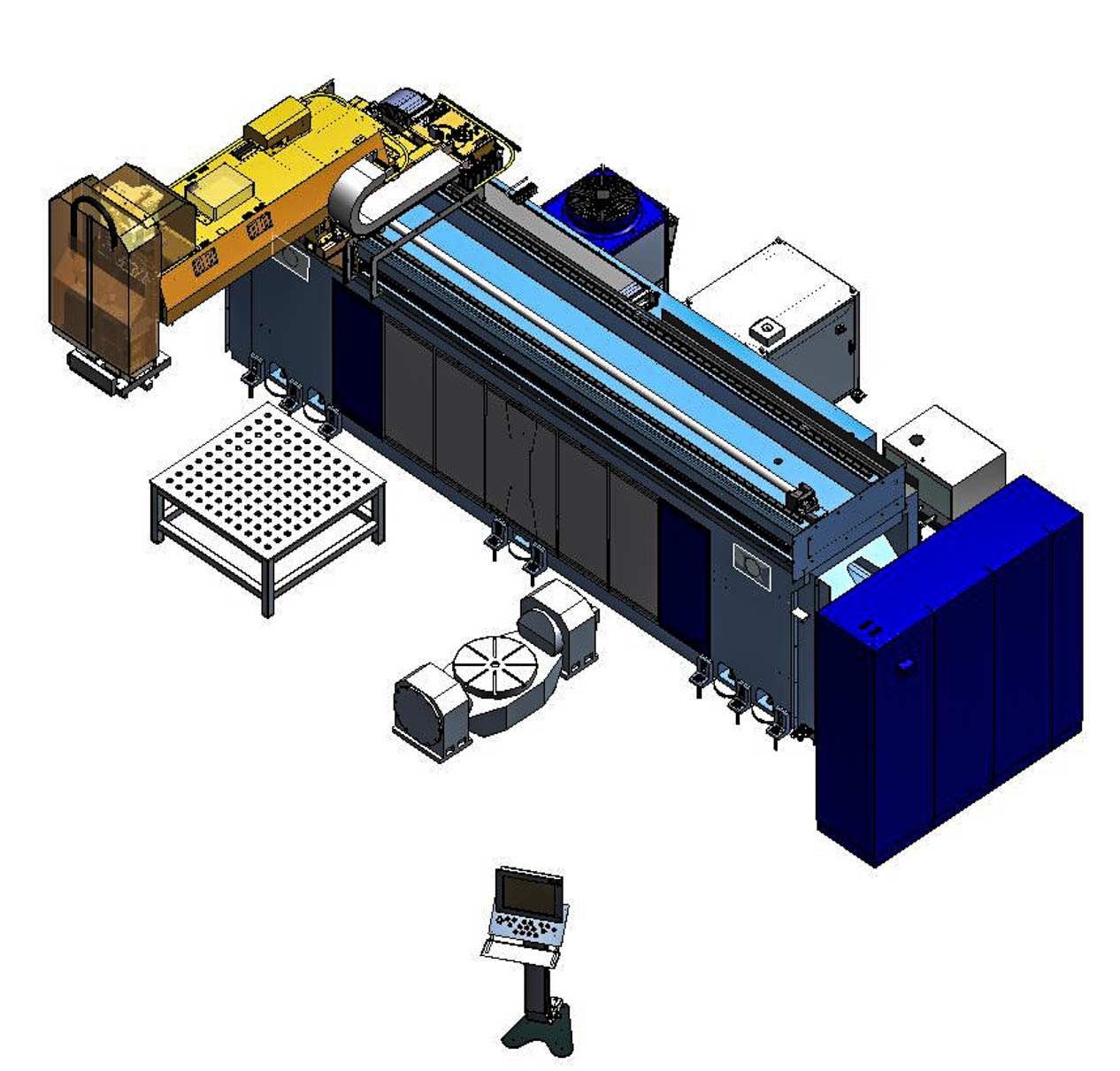

As part of the Horizon project, there is a research project known as Borealis, entirely dedicated to future machines that will be able to achieve production volumes with a maximum capacity of two thousand cm3 per hour, and an efficiency enabling 40% energy savings and up to 75% savings in the materials. In particular, products characterized by a complex design will be created (through just one cycle) by means of mechatronics (which include mechanical and electronic properties) and laser processes, with certified quality and with machine sizes up to 4.5m in width.

It’s not difficult to understand that at the heart of this project is additive manufacturing. Being a pioneer in this production technology, Avio Aero is taking part in this project with a role of “pilot end-user” together with other companies in the automotive and medical sectors. One type of additive technology in particular, well-known in Avio Aero and in its laboratories, is Laser Deposition; namely the application of metal powder by means of deposition using a laser beam.

“Gambling on our multi-year expertise in mechatronic, advanced manufacturing and laser processes, added to our R&D efforts, we developed the concept of the new Direct Deposition machine in order to maximize benefits coming from this disruptive technology” says Paolo Calefati, Innovation Manager and Borealis Project Coordinator for the Italian company Prima Industrie. “This represents a direct contribution to the technology’s growth from an industrial point of view, in collaboration with Additive Manufacturing early adopters and main users.”

Practically, the Borealis project seeks to build the largest machine in additive manufacturing, equipped with Laser Deposition technology, on a scale never seen before. Together with this, it is proposed to amplify all the distinctive and highly competitive additive features: design freedom, reduction in weight and material consumption (i.e. powder reuse), and flexibility of the laser-based process so that it can be applicable to as many industrial sectors as possible.

“We had the idea that Borealis could be used to adopt additive solutions for our products such as cases and housings (accessory or power transmission housings and casings for aircraft or helicopter engines, ed.) which have truly impressive dimensions for certain engine programs. Dimensions which unfortunately we can’t currently deal with using additive manufacturing, and for this reason we are a very important end-user for those designing this machine. It’s also essential for us to explore this field”, explained Simona Corigliano, Materials Science Lead Engineer at Avio Aero in Brindisi.

Borealis focuses on cutting-edge production technology, but with close attention to the environment: all project activities have the strict requirement to reduce CO2 emissions responsible for greenhouses gases, both direct and indirect. And the project also benefits from the participation and collaboration of many companies as well as universities.

The Polytechnic of Turin, given its vocation for innovative research, is actively taking part in the study alongside Avio Aero, as Sara Biamino, Associate Professor of Materials Science and Technology, explained. “We are aware of the great challenge that Borealis represents in the field of Additive Manufacturing, and we are providing input to the project based on our experience in the characterization of metallic materials produced using additive processes, actively contributing to the optimization of the process parameters for this new machine, in this case for the efficient production of aviation engine components.”

The project also involves small and medium-sized enterprises, such as the start-up Iris, which is currently hosting the large machine under construction. “From the start, Iris has tried to combine innovation and sustainability within the Borealis project. Our participation in the project has definitely driven and helped the company to grow, as well as training young, qualified personnel”, stated the CEO of the start-up specializing in manufacturing technologies, Manuel Lai. “We have developed and analyzed the materials, powders, and laser use, having the good fortune to be able to interact with the prototype housed in our laboratories. This experience offers us opportunities to grow in the Additive Manufacturing development and application market”.

Borealis is explicitly an environmentally-sustainable project, and this is also seen in the approach asked to the participants: every action and every development stage of the project must be constantly monitored from a CO2 emissions point of view, and environmentally offset. In fact, all the partners engage in reforestation initiatives or actions which generate new green spaces.

This is an initiative which Avio Aero has enthusiastically undertaken through the Rivalta Engineering R&D and the Operations Management Leadership Program teams: all the engineers have been put to work setting up tables and benches, and planting trees and flowers to create two new green break areas.

For some days, even aeronautical design experts and manufacturing engineers could transform into garden designers!