Invent

Tag and Follow

This isn’t another social network for industry, but rather a new tool on Avio Aero’s path towards digitalization.

Feb 2018

It’s called Taranta, first and foremost because one of the components of the new app adopted inside the Brindisi (Apulia, Italy) Repair center is nicknamed “spider”, and is in fact its shape recalls the legs of a spider. And also because of the place where the app was created: the ‘Taranta’ is one of the most famous folk dances in Salento, the area in the region of Puglia where the Avio Aero facility is located. That’s the production center for casings for large commercial engines, the service and assistance center for military engines and for industrial or marine gas turbines, and precisely the site where, since the summer of 2016, a second repair center is up and running, following the one in Pomigliano d’Arco (Naples), for aircraft engine components.

The technology underlying the functioning of the app isn’t new; it’s called RFID (Radio Frequency IDentification), and enables data acquisition, transmission or storage through electrical or electromagnetic signals. “It’s something very common. Just think about the systems used for the Telepass electronic toll or at the Decathlon checkouts, they’re pretty similar”, explained Daniela Napolitano, Taranta IT Specialist Project Leader.

Daniela studied Computer Engineering, despite having entered the business world by working in admin, and joined the IT team in Brindisi less than a year ago, working together with GE Digital, as well as with IT Specialists at the Rivalta headquarters. However, in order to kick off this pilot project, collaboration with the Manufacturing Engineers at the Salento Repair center was essential, as well as with the factory teams dealing with safety, environment and planning, EHS and Facilities. In particular, she collaborates with specialist from the Materials Plan & Execution team, like Gianluca Proscia, studying digital solutions for the repair shop typical processes: “the time we spent to search for engines’ parts that we repair or overhaul, that we spent for their tracking and activities planning is a key factor, and optimizing that time with smart tools is a win-win for both our teams and the customers.”

At this point, it is tempting to underestimate innovation: basically there is little deviation from traditional systems used to track and follow goods and products within stores and factories. However, we need to consider that the aviation industry has atypical dimensions and materials, and is very complex: in fact we’re talking about parts of aircraft engines, very different from items contained in an Amazon package, for example (engine parts are made of materials which are difficult to tag and sometimes have magnetic properties). And with particularly high costs (both in terms of the parts themselves and the processes). Not to mention rather unusual routes, lead times and stock.

RFID enables information to be collected on the movements, stock and location of an item, generating a log. The technology is used in other GE Aviation centers; some facilities in the United States use it to track parts in transit from one industrial site to another. “But the smartphone app that we’ve developed is a new development and it dialogues with Predix”, explained Daniela, “and obviously it isn’t public. At the end of the pilot project it will be available for download from GE Store”.

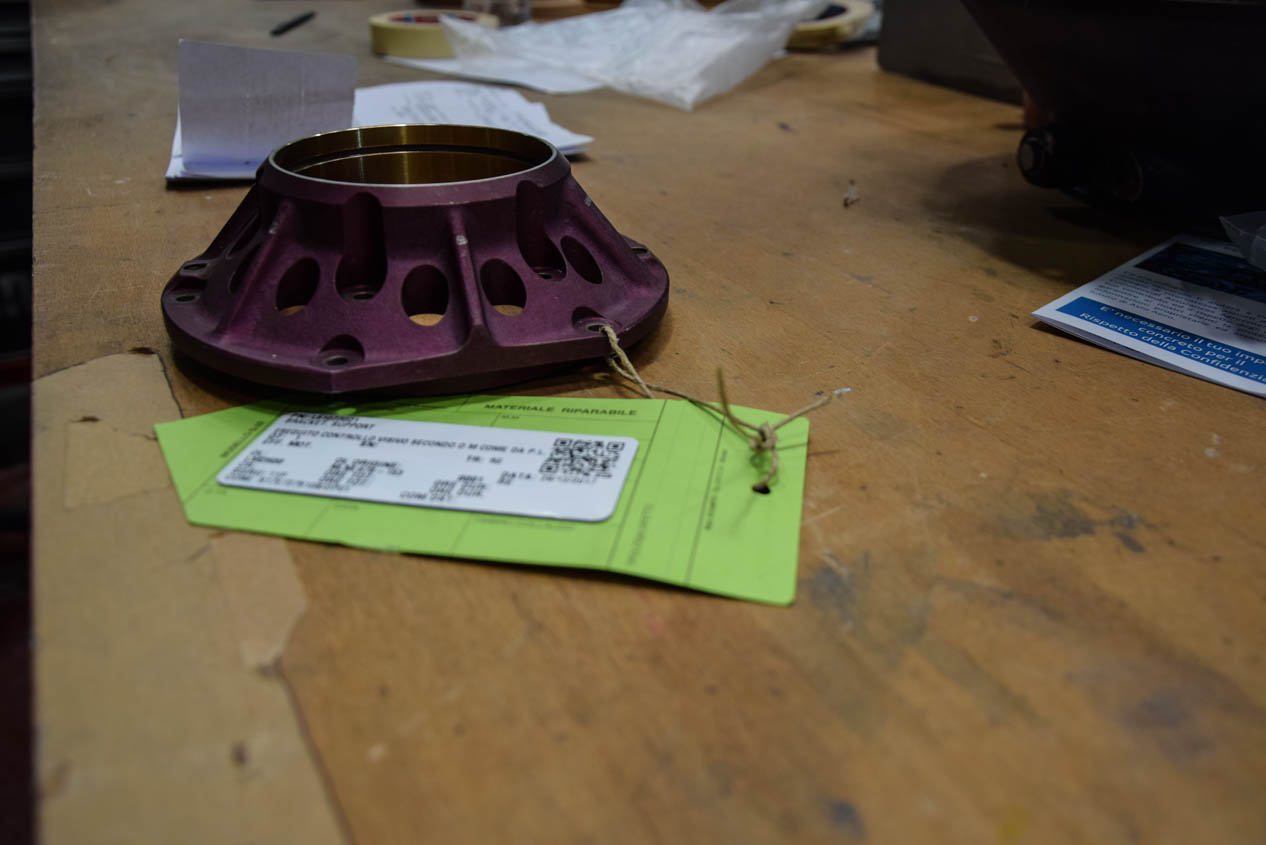

So this tool, starting from certain pilot areas in the Repair center, has the ambitious objective of giving an electronic identity to every single incoming part of every engine. Once disassembled, the operators that assess it - i.e. evaluate which parts need to undergo processing - “tag” the individual parts using sticky tags with very thin antennas, produced using special printers and similar to labels found on new clothes. “The size is similar to that of barcodes or magnetic codes in stores, but these contain passive antennas, meaning they don’t have batteries, which collect data and transmit it to the RFID readers”.

The tag reader devices, with a predefined range of 2 meters, can be both mobile and fixed. The fixed readers are divided into passageways, simply entrance doors or transit areas from one processing area to another, and the famous spiders, which are located in the areas where pallets containing numerous parts undergoing processing are situated. The mobile device that reads the tags is actually the Taranta app: “it’s downloaded and used from a company mobile phone, through authentication using your individual company log-in”, continued Daniela, showing a holder with handle that the smartphone fits into. It’s like a gun with a wide screen instead of a barrel. “The operator or anyone equipped with the mobile reader or just a smartphone that can read QR codes (this is also printed on one side of the label, ed.) can go up to an individual item and obtain all the relevant information collected from when the item entered the shop. Or even earlier, if it was tagged previously, and a search can be carried out by entering the ID number registered for that part”.

The architecture on which RFID is based is in fact a development of the system that plans and tracks production, improved by becoming mobile, trackable and shared in real-time on Predix. It is optimized on GE Store: “it’s a highly integrable product since the same software and hardware can be used to export it to other facilities, GE businesses or even clients that use Predix”, confirmed Angelo Spalluto, IT Leader at Avio Aero Brindisi. “In the long term it will enable us to automate, and therefore speed up, tracking or data entry which up to now has been done manually (also minimizing mistakes). It’s staring from the Repair center areas, but can be extended to the Service Center and to any production business that still uses less efficient methods”. Brilliant, isn’t it?